Dublok double block and bleed valve assemblies have three valves - primary isolation, secondary isolation and bleed - all integrated into a single block.

| Availability: | |

|---|---|

| Quantity: | |

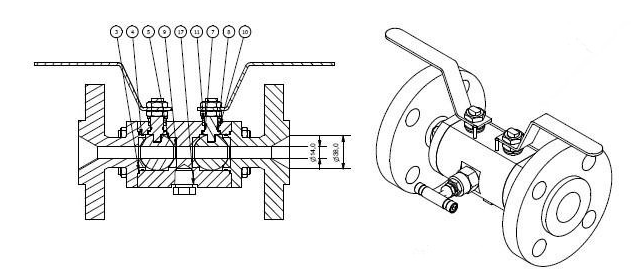

This valve is a forged valve body floating DBB valve specifically designed to provide effective isolation and drainage in high-pressure systems. It has a lever operating mechanism that is easy to control, ensuring simple and reliable operation in both open and closed positions. It is made of high-quality materials such as A105, F304, or F316, which have excellent strength, corrosion resistance, and durability, making it an ideal choice for harsh environments.

The floating ball design of this valve ensures excellent sealing performance, while the dual block and discharge (DBB) function provides dual isolation and safe exhaust capabilities, providing additional protection and leak prevention. This makes it the perfect solution for industrial applications that require reliable sealing, safety, and durability.

● Forged body construction for high strength and durability.

● Floating ball design ensures secure sealing and isolation.

● Lever-operated for easy control in harsh conditions.

NO | Part name | Material | |

| GB | ASTM | ||

| 1 | Valve body | WCB | A2116-WCB |

| 2 | Sealing ring | PTFE | PTFE |

| 3 | Sphere | 1C18Ni9Ti | SS304 |

| 4 | Nut | 35 | A194-2H |

| 5 | Stud | 35CrMoA | A193-B7 |

| 6 | The stone body | WCB | A216-WCB |

| 7 | Shim | Graphite + stainless steel | B12.10-304F/.G |

| 8 | Filler | PTFE | PTFE |

| 9 | Packing gland | WCB | A2116-WCB |

| 10 | Locating piece | 25 | A105 |

| 11 | Ring | 65Mn | AISI 1066 |

| 12 | Handle | K33 | A47-667 Gr.32510 |

| 13 | Valve stem | 1Cr33 | A276-410 |

| 14 | Screw | 35 | A193-B7 |

| Thrust washer | PTFE | PTFE | |

Main Dimensions

| Nominal diameter | 15 | 20 | 25 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 |

| d1 | 13 | 19 | 25 | 38 | 64 | 64 | 76 | 102 | 127 | 152 | 203 |

| L | 108 | 117 | 127 | 165 | 191 | 191 | 203 | 229 | 356 | 394 | 457 |

| H | 59 | 63 | 75 | 95 | 142 | 142 | 152 | 178 | 252 | 272 | 342 |

| W | 130 | 130 | 160 | 230 | 400 | 400 | 400 | 650 | 1050 | 1050 | 1410 |

| Wt(kg) | 2.5 | 3 | 5 | 7 | 15 | 19 | 19 | 33 | 58 | 93 | 160 |

| Primari Isonation | Secondary Isolation | Drain |

| Ball | Ball | Needle |

| Needle | Needle | Needle |

| Ball | Needle | Needle |

| Size: | 2" ~ 24"(DN50~DN400) | ||||||||

| Pressure: | ANSI Ratings 150# ~ 2500# (PN16~PN420) | ||||||||

| Structure: | 3 Pieces Body Design | ||||||||

| Connections: | RF RTJ BW Connections | ||||||||

| Body Material: | ASTM A105, A182 304, A182 316, A182 304L, A182 316L,A182 F6A,A182,F51,A182 F53,F22 Alloy | ||||||||

| Ball Material: | ASTM A105, A182 304, A182 316, A182 304L, A182 316L,A182 F6A,A182,F51,A182 F53,F22 Alloy | ||||||||

| Seats Material: | PTFE/ RTFE(≤120ºC) , NYLON (≤80ºC), PEEK/PPL (≤250ºC) | ||||||||

| Driving means: | Manual,worm gear.etc. | ||||||||

| Flow direction: | bidirectional | ||||||||

| Applicable medium: | Seawater,all kinds of harsh environment | ||||||||

The valve is available in a wide size range, from 2" to 24", to accommodate various industrial needs.

This valve is available in high-quality materials, including A105, F304, and F316, offering superior strength, corrosion resistance, and durability.

Our forged floating ball valves for dual block applications are designed for reliable long-term use in high-pressure environments. We offer customized options to meet the specific needs of various industries, ensuring optimal performance in any application. With a commitment to validated quality, our valves are manufactured under strict standards to provide exceptional reliability and durability.