| Availability: | |

|---|---|

| Quantity: | |

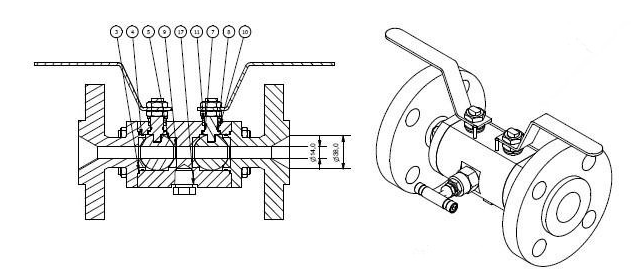

Dublok double block and bleed valve assemblies consist of three integrated valves: a primary isolation valve, a secondary isolation valve, and a bleed valve. If necessary, the inlet or outlet end connection can include a spring-loaded in-line piston check valve. The end connectors are interchangeable and can be customized to meet specific requirements.

Our Ball valve double block and bleed assembly is highly compact and is recommended for general services. The valve can incorporate Needle, Globe, Gate, and Check valves into the design to meet specific duty specifications as required.

● ISO 5211 Mounting Pad: Facilitates straightforward installation of actuators for automated operation.

● Double Block and Bleed Design: Ensures exceptional isolation to prevent leaks and maintain pressure.

● High-Pressure Service: Engineered for high-pressure applications, ensuring durability and safety.

NO | Part name | Material | |

| GB | ASTM | ||

| 1 | Valve body | WCB | A2116-WCB |

| 2 | Sealing ring | PTFE | PTFE |

| 3 | Sphere | 1C18Ni9Ti | SS304 |

| 4 | Nut | 35 | A194-2H |

| 5 | Stud | 35CrMoA | A193-B7 |

| 6 | The stone body | WCB | A216-WCB |

| 7 | Shim | Graphite + stainless steel | B12.10-304F/.G |

| 8 | Filler | PTFE | PTFE |

| 9 | Packing gland | WCB | A2116-WCB |

| 10 | Locating piece | 25 | A105 |

| 11 | Ring | 65Mn | AISI 1066 |

| 12 | Handle | K33 | A47-667 Gr.32510 |

| 13 | Valve stem | 1Cr33 | A276-410 |

| 14 | Screw | 35 | A193-B7 |

| Thrust washer | PTFE | PTFE | |

Main Dimensions

| Nominal diameter | 15 | 20 | 25 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 |

| d1 | 13 | 19 | 25 | 38 | 64 | 64 | 76 | 102 | 127 | 152 | 203 |

| L | 108 | 117 | 127 | 165 | 191 | 191 | 203 | 229 | 356 | 394 | 457 |

| H | 59 | 63 | 75 | 95 | 142 | 142 | 152 | 178 | 252 | 272 | 342 |

| W | 130 | 130 | 160 | 230 | 400 | 400 | 400 | 650 | 1050 | 1050 | 1410 |

| Wt(kg) | 2.5 | 3 | 5 | 7 | 15 | 19 | 19 | 33 | 58 | 93 | 160 |

| Primari Isonation | Secondary Isolation | Drain |

| Ball | Ball | Needle |

| Needle | Needle | Needle |

| Ball | Needle | Needle |

| Size: | 2" ~ 24"(DN50~DN400) | ||||||||

| Pressure: | ANSI Ratings 150# ~ 2500# (PN16~PN420) | ||||||||

| Structure: | 3 Pieces Body Design | ||||||||

| Connections: | RF RTJ BW Connections | ||||||||

| Body Material: | ASTM A105, A182 304, A182 316, A182 304L, A182 316L,A182 F6A,A182,F51,A182 F53,F22 Alloy | ||||||||

| Ball Material: | ASTM A105, A182 304, A182 316, A182 304L, A182 316L,A182 F6A,A182,F51,A182 F53,F22 Alloy | ||||||||

| Seats Material: | PTFE/ RTFE(≤120ºC) , NYLON (≤80ºC), PEEK/PPL (≤250ºC) | ||||||||

| Driving means: | Manual,worm gear.etc. | ||||||||

| Flow direction: | bidirectional | ||||||||

| Applicable medium: | Seawater,all kinds of harsh environment | ||||||||

Q1:What applications is it suitable for?

This valve is perfect for isolation and venting in pipelines, especially in critical systems where safety and leak prevention are paramount.

Q2:What are the pressure ratings?

It is available in ANSI ratings for high-pressure service, making it suitable for demanding industrial applications.

Our double block and bleed (DBB) ball valve ensures reliable sealing under pressure, preventing leaks and ensuring safe and efficient operation. We customize valve configurations based on your specific system requirements, optimizing performance to meet your unique needs. Made from high-quality materials, our valves are designed to be robust and durable, suitable for critical high-pressure applications, providing long-term reliability. In challenging industrial environments, you can trust us to achieve safe isolation, leak prevention, and efficient maintenance.