| Availability: | |

|---|---|

| Quantity: | |

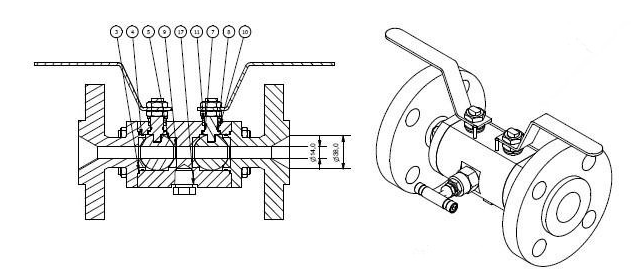

This valve is constructed from Nai-Lok Super Duplex Steel F51, known for its excellent resistance to corrosion and high pressure. It features a threaded and welded connection design, providing flexibility for different installation requirements. With support for both DBB and SBB configurations, this valve ensures leak prevention and double isolation for safer operations in critical systems. Its durability and performance make it the ideal choice for applications that require long-lasting, reliable valve solutions.

● Super Duplex Steel F51 provides outstanding corrosion resistance.

● Threaded and welded connections ensure secure, stable installation.

● The double block and bleed design effectively prevents leakage.

NO | Part name | Material | |

| GB | ASTM | ||

| 1 | Valve body | WCB | A2116-WCB |

| 2 | Sealing ring | PTFE | PTFE |

| 3 | Sphere | 1C18Ni9Ti | SS304 |

| 4 | Nut | 35 | A194-2H |

| 5 | Stud | 35CrMoA | A193-B7 |

| 6 | The stone body | WCB | A216-WCB |

| 7 | Shim | Graphite + stainless steel | B12.10-304F/.G |

| 8 | Filler | PTFE | PTFE |

| 9 | Packing gland | WCB | A2116-WCB |

| 10 | Locating piece | 25 | A105 |

| 11 | Ring | 65Mn | AISI 1066 |

| 12 | Handle | K33 | A47-667 Gr.32510 |

| 13 | Valve stem | 1Cr33 | A276-410 |

| 14 | Screw | 35 | A193-B7 |

| Thrust washer | PTFE | PTFE | |

| Nominal diameter | 15 | 20 | 25 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 |

| d1 | 13 | 19 | 25 | 38 | 64 | 64 | 76 | 102 | 127 | 152 | 203 |

| L | 108 | 117 | 127 | 165 | 191 | 191 | 203 | 229 | 356 | 394 | 457 |

| H | 59 | 63 | 75 | 95 | 142 | 142 | 152 | 178 | 252 | 272 | 342 |

| W | 130 | 130 | 160 | 230 | 400 | 400 | 400 | 650 | 1050 | 1050 | 1410 |

| Wt(kg) | 2.5 | 3 | 5 | 7 | 15 | 19 | 19 | 33 | 58 | 93 | 160 |

| Primari Isonation | Secondary Isolation | Drain |

| Ball | Ball | Needle |

| Needle | Needle | Needle |

| Ball | Needle | Needle |

| Size: | 2" ~ 24"(DN50~DN400) | ||||||||

| Pressure: | ANSI Ratings 150# ~ 2500# (PN16~PN420) | ||||||||

| Structure: | 3 Pieces Body Design | ||||||||

| Connections: | RF RTJ BW Connections | ||||||||

| Body Material: | ASTM A105, A182 304, A182 316, A182 304L, A182 316L,A182 F6A,A182,F51,A182 F53,F22 Alloy | ||||||||

| Ball Material: | ASTM A105, A182 304, A182 316, A182 304L, A182 316L,A182 F6A,A182,F51,A182 F53,F22 Alloy | ||||||||

| Seats Material: | PTFE/ RTFE(≤120ºC) , NYLON (≤80ºC), PEEK/PPL (≤250ºC) | ||||||||

| Driving means: | Manual,worm gear.etc. | ||||||||

| Flow direction: | bidirectional | ||||||||

| Applicable medium: | Seawater,all kinds of harsh environment | ||||||||

Q1:What makes this valve suitable for harsh environments?

Super Duplex Steel F51 offers exceptional resistance to corrosion, making it ideal for use in aggressive, high-pressure environments.

Q2:What connection types are available?

This valve is available in both threaded and welded connection types, providing flexibility for various installation needs.

We offer custom solutions tailored to meet the demands of extreme conditions, ensuring superior performance in harsh environments. Our valves are made from advanced materials like Super Duplex Steel F51, providing exceptional corrosion resistance and durability. With efficient service and fast delivery options, we ensure your projects run smoothly and on time.