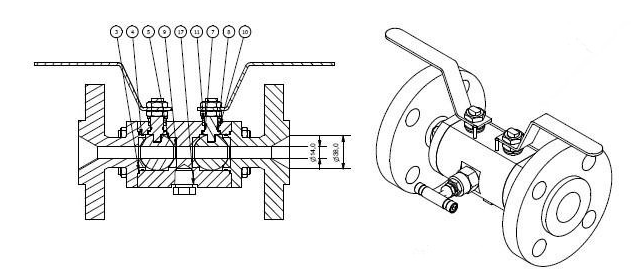

The double block and bleed valve have evolved to replace and add the process of bolting together individual valves to make the valves in one body .It saved a lot of space and material.

| Availability: | |

|---|---|

| Quantity: | |

The DBB Ball Valve is designed for chemical injection systems, offering reliable isolation and leak prevention. It integrates double block and bleed (DBB) functionality with gear operation, ensuring smooth control even in high-torque applications. The valve features flexible installation options with both Buttweld (BW) and Socket Weld (SW) connections.

Equipped with an anti-static design, it minimizes the risk of static buildup when handling flammable chemicals, thereby enhancing safety. Constructed from high-quality materials, the valve is engineered to endure harsh industrial environments, making it a dependable option for chemical injection in industries such as oil and gas, petrochemicals, and chemical processing.

● Anti-Static Design: Prevents static buildup, ensuring safe operation when handling flammable or volatile chemicals.

● Double Block and Bleed (DBB) Functionality: Provides two layers of isolation, enhancing leak prevention and safety during maintenance.

● Flexible Connection Options: Available with both Buttweld (BW) and Socket Weld (SW) connections for easy integration into various systems.

NO | Part name | Material | |

| GB | ASTM | ||

| 1 | Valve body | WCB | A2116-WCB |

| 2 | Sealing ring | PTFE | PTFE |

| 3 | Sphere | 1C18Ni9Ti | SS304 |

| 4 | Nut | 35 | A194-2H |

| 5 | Stud | 35CrMoA | A193-B7 |

| 6 | The stone body | WCB | A216-WCB |

| 7 | Shim | Graphite + stainless steel | B12.10-304F/.G |

| 8 | Filler | PTFE | PTFE |

| 9 | Packing gland | WCB | A2116-WCB |

| 10 | Locating piece | 25 | A105 |

| 11 | Ring | 65Mn | AISI 1066 |

| 12 | Handle | K33 | A47-667 Gr.32510 |

| 13 | Valve stem | 1Cr33 | A276-410 |

| 14 | Screw | 35 | A193-B7 |

| Thrust washer | PTFE | PTFE | |

Main Dimensions

| Nominal diameter | 15 | 20 | 25 | 40 | 50 | 65 | 80 | 100 | 125 | 150 | 200 |

| d1 | 13 | 19 | 25 | 38 | 64 | 64 | 76 | 102 | 127 | 152 | 203 |

| L | 108 | 117 | 127 | 165 | 191 | 191 | 203 | 229 | 356 | 394 | 457 |

| H | 59 | 63 | 75 | 95 | 142 | 142 | 152 | 178 | 252 | 272 | 342 |

| W | 130 | 130 | 160 | 230 | 400 | 400 | 400 | 650 | 1050 | 1050 | 1410 |

| Wt(kg) | 2.5 | 3 | 5 | 7 | 15 | 19 | 19 | 33 | 58 | 93 | 160 |

| Primari Isonation | Secondary Isolation | Drain |

| Ball | Ball | Needle |

| Needle | Needle | Needle |

| Ball | Needle | Needle |

| Size: | 2" ~ 24"(DN50~DN400) | ||||||||

| Pressure: | ANSI Ratings 150# ~ 2500# (PN16~PN420) | ||||||||

| Structure: | 3 Pieces Body Design | ||||||||

| Connections: | RF RTJ BW Connections | ||||||||

| Body Material: | ASTM A105, A182 304, A182 316, A182 304L, A182 316L,A182 F6A,A182,F51,A182 F53,F22 Alloy | ||||||||

| Ball Material: | ASTM A105, A182 304, A182 316, A182 304L, A182 316L,A182 F6A,A182,F51,A182 F53,F22 Alloy | ||||||||

| Seats Material: | PTFE/ RTFE(≤120ºC) , NYLON (≤80ºC), PEEK/PPL (≤250ºC) | ||||||||

| Driving means: | Manual,worm gear.etc. | ||||||||

| Flow direction: | bidirectional | ||||||||

| Applicable medium: | Seawater,all kinds of harsh environment | ||||||||

Q1:What is a DBB Ball Valve?

A DBB (Double Block and Bleed) Ball Valve provides two layers of isolation, ensuring that fluids are safely contained and preventing leakage during maintenance or operation.

Q2:What is the benefit of using a gear-operated ball valve?

The gear-operated mechanism ensures smooth operation, especially for larger valve sizes or applications requiring higher torque, providing more control and ease of use.

Q3:How does the anti-static design improve safety?

The anti-static design prevents the buildup of static electricity, reducing the risk of sparks or ignition when handling flammable or volatile chemicals.

Our DBB Ball Valve is designed with a strong emphasis on safety and performance, featuring advanced attributes such as an anti-static design and double block and bleed (DBB) capabilities. We recognize that each application has its own distinct requirements, which is why we provide tailored solutions that are customized to your particular needs. Should you need adaptable installation options, including Buttweld (BW) and Socket Weld (SW) connections, or if you're seeking fire-safe certifications for environments with high risk, we guarantee that your system will function safely and effectively. Opt for our reliable, high-performance valves, engineered to satisfy the rigorous demands of the most critical applications.