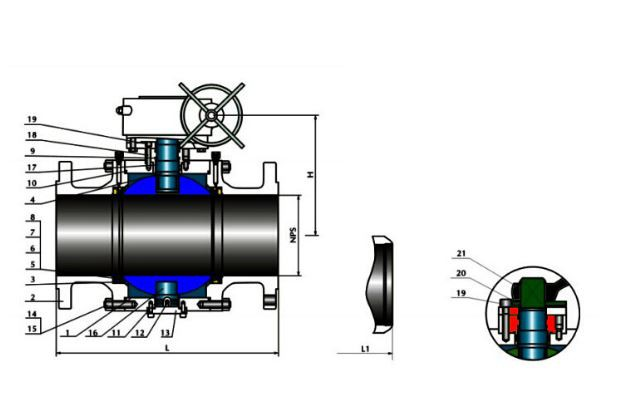

DescriptionThree pieces body. Valve is designed in accordance with the requirements of API 6D for pipeline service. Anti-static and anti blow-out stem design. Seat design gives perfect tighness and is available as either self-relieving type or double piston effect type. Disign minimizes friction leading to low operating torque. Available as double block and bleed execution,which allows for venting and draining of ling fluid from the body cavity. Avaiable Full and Reduced bore. Ball valves firesafe tested according to BS EN 12266-2,API 6FA and API 607. Electric,pneumatic and hydravlic actuators are available on customer's requirement...

| Availability: | |

|---|---|

| Quantity: | |

Fixed ball valves are a new generation of high-performance ball valves suitable for long-distance pipelines and general industrial pipelines. In their design, special considerations have been given to their strength, safety, and resistance to harsh environments, making them suitable for various corrosive and non-corrosive media. Compared to floating ball valves, when in operation, the force exerted by the fluid pressure in front of the valve on the ball is fully transferred to the bearings, preventing the ball from moving towards the seat. Therefore, the seat does not bear excessive pressure, resulting in a smaller torque for the fixed ball valve, less deformation of the seat, stable sealing performance, and a long service life, making them suitable for high-pressure and large-diameter applications. The advanced spring pre-seating assembly has self-tightening characteristics, achieving upstream sealing. Each valve has two seats, capable of sealing in both directions, thus having no flow direction restrictions and being bidirectional. These valves are typically installed horizontally.

● Standard Port Design: Ensures efficient flow and reduced resistance, perfect for uninterrupted fluid regulation in various applications.

● Flexible Connections:Available with threaded, welded, and flanged ends, providing easy integration into various pipeline systems.

●Flow Efficiency:The standard port design minimizes pressure drops and enhances flow characteristics, ensuring smooth and stable pipeline operation.

| No | Part Name | ASTM Material | ||

| Carbon steel | 18Cr-19Ni-2Mo | Low temperature steel | ||

| 1 | Body | A216-WCB | A351-CF8M | A352-LCB |

| 2 | Bonnet | A216-WCB | A351-CF8M | A352-LCB |

| 3 | Ball | A182-F304 | A182-F316 | A182-F314 |

| 4 | Stem | A276-304 | A276-316 | A276-304 |

| 5 | Seat | A105+ENP | A182-F316 | A350-LF2+ENP |

| 6 | Stem insert | Class filled PTFE | A313-304 | |

| 7 | Seat spring | A313-304 | Inconel X-750 | A313-304 |

| 8 | O-ring | NBR | PTFE | PTFE |

| 9 | O-ring | NBR | PTFE | PTFE |

| 10 | Gasket | Graphite+304 | Graphite+316 | Graphite+304 |

| 12 | Spring | A313-304 | A313-316 | A313-304 |

| 13 | Grounding plunger | A216-WCB | A182-F316 | A182-F304 |

| 14 | Stud | A193-B7 | A193-B8 | A320-L7 |

| 15 | Nut | A194-2H | A194 8 | A194 4 |

| 16 | Trunnion | A276-304 | A276-316 | A276-304 |

| 17 | Trunnion bearing | 304+PTFE | 316+PTFE | 304+PTFE |

| 18 | Gland flange | A193-B7 | A193-8 | A193-B7 |

| 19 | Gland bolt | A193-B7 | A193-B8 | A193-B7 |

| 20 | Stop plate | Carbon steel | Carbon steel+Zn | Carbon steel |

| 21 | Handle | Carbon steel | ||

Main Dimensions

| Size | in | 2 | 2 1/2 | 3 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 24 | 26 | 28 | 30 | 32 | 36 |

| mm | 50 | 65 | 80 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 650 | 700 | 750 | 800 | 900 | |

| L(RF) | in | 7 | 7.5 | 8 | 9 | 15.5 | 18 | 21 | 24 | 27 | 30 | 34 | 36 | 42 | 45 | 49 | 51 | 54 | 60 |

| mm | 178 | 190 | 203 | 229 | 394 | 457 | 533 | 610 | 686 | 762 | 864 | 914 | 1067 | 1143 | 1245 | 1295 | 1372 | 1524 | |

| L1(BW) | in | 8.5 | 9.5 | 11.12 | 12 | 18 | 20.5 | 22 | 25 | 30 | 33 | 36 | 39 | 45 | 49 | 53 | 55 | 60 | 68 |

| mm | 216 | 241 | 283 | 305 | 457 | 521 | 559 | 635 | 762 | 838 | 814 | 991 | 1143 | 1245 | 1346 | 1397 | 1524 | 1727 | |

| H | in | 7 | 7.5 | 8.25 | 9.25 | 20.88 | 24.62 | 25.62 | 30.75 | 31 | 36.25 | 38.25 | 43.38 | 5.25 | 50.75 | 55.12 | 64.12 | 70.88 | 80.75 |

| mm | 177 | 190 | 210 | 235 | 530 | 625 | 650 | 780 | 790 | 920 | 970 | 1100 | 1150 | 1290 | 1400 | 1630 | 1840 | 2050 | |

| W | in | 14 | 16 | 20 | 20 | 24 | 24 | 24 | 24 | 32 | 32 | 32 | 32 | 32 | 32 | 32 | 32 | 32 | 32 |

| mm | 350 | 400 | 500 | 500 | 600 | 600 | 600 | 600 | 800 | 800 | 800 | 800 | 800 | 800 | 800 | 800 | 800 | 800 | |

| WT(Kg) | RF | 15 | 19 | 27 | 38 | 81 | 140 | 160 | 205 | 260 | 390 | 510 | 750 | 1200 | 1400 | 1860 | 2100 | 2530 | 2970 |

| BW | 13.5 | 15.5 | 24.5 | 32.5 | 76 | 132 | 147 | 182 | 241 | 370 | 495 | 726 | 1125 | 1250 | 1640 | 1930 | 2390 | 276 |

| TYPE | TRUNNION BALL VALVE | SIZE | 1/2"--48"(DN15--DN1200) |

| STRUCTURE | TRUNNION BALL VALVE | PRESSURE RATING | ANSI CLASS 150--2500(1.6MPa--42.0MPa) |

| CONNECTION | THREADED, WELDED,FLANGE END | FUCTION | BLOW-DOWN VALVE |

| OPERATION | MANUAL,PNEUMATIC,ELECTRIC | APPLICATION | INDUSTRIAL USAGE |

| PRODUCTION CAPACITY | 1000000PCSNEAR | PACKAGE | PLYWOOD CASE |

| WARRANTY PERIOD | 12 MONTHS | TRADE MARK | GOOLE,OEM |

| ORIGIN | WENZHOU ZHEJIANG | HS CODE | 84819090 |

Q:What is the advantage of the Standard Port design?Standard Port

The Standard Port design minimizes flow resistance and prevents any turbulence, which ensures smoother, more efficient flow in the pipeline.

Q:How does the valve handle sealing at high pressure?

The valve is equipped with a self-relieving seat design that ensures effective sealing under high pressure, preventing leakage and reducing operational torque.

In designing our 3 PCS forged steel ball valves, we focus on innovation, designed to reduce wear and ensure operational reliability, while providing efficient fluid control. The eartrunion installation design and standard port configuration allow our valves to perform well in high demand applications. Our team focuses on providing customized solutions that ensure meeting your unique needs in a precise and professional manner.