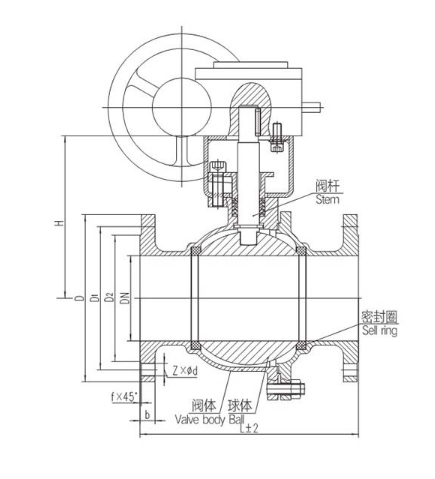

Split body reduce bore trunnion mounted ball valve have two piece and three piece body structure.middle part is bolt connection, RPTFE seal insert into stainless steel ring with spring .keep good sealling...

| Availability: | |

|---|---|

| Quantity: | |

The top mounted eccentric hemispherical valve utilizes an eccentric valve body, eccentric ball, and valve seat. When the valve stem rotates, it will automatically center around a common trajectory, and the closer it closes, the better the sealing effect. The ball valve and valve seat of the valve are completely separated, eliminating the wear of the sealing ring and overcoming the problem of traditional ball valve seats and sealing surfaces always being worn. The non-metallic elastic material is embedded in the metal valve seat, and the metal surface of the valve seat is well protected. This product is particularly suitable for media such as steel, aluminum, fiber, small solid particles, pulp, coal ash, petroleum gas, etc.

●Its structure adopts the eccentric wedge principle to achieve the purpose of locking:adjusting, and closing through the transmission mechanism. The sealing pair is a metal face ring with a hard contact seal. The double eccentric structure is located in the ball storage chamber when opening, with a large flow cross-section, and the valve is not washed out. When closing, the valve core is not washed out. When opening, the spherical surface of the valve core gradually moves along the valve seat, effectively removing scaling obstacles and achieving reliable sealing.

●The hemisphere of the valve:is made of bimetallic material, with different alloys deposited on the base material. The valve seat is also subjected to corresponding surfacing and special treatment. The sealing surface group is composed of various types such as anti-corrosion, wear-resistant, and high-strength, meeting the needs of different occasions

●Tightly sealed:delivering harmful gases with zero leakage

| Item | Part. Name | Material |

| 1 | Bonnet | PE |

| 2 | Extension pipe | st37 |

| 3 | Body | st37 |

| 4 | Flat washer | st37 |

| 5 | Butterfly Spring | 60Si2MnA |

| 6 | Ball seat | SS202 |

| 7 | O-ring | EPDM |

| 8 | Ball washer | PTFE+20%C |

| 9 | Ball | SS304 |

| 10 | Stem washer | PTFE+20%C |

| 11 | Stem sleeve | st37 |

| 12 | Stem | SS410 |

| 13 | Stem ring | PTFE+20%C |

| 14 | Stem O-ring | FPM |

| 15 | Sleeve | st37 |

| 16 | Positioning PIN | ASTM1035 |

| 17 | Handle | st37 |

| 18 | Washer | Q235A |

| 19 | Nut | Q235A |

| 20 | Handle cap | ABS |

Main Dimensions

| Size | in | 2 | 2 1/2 | 3 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 24 | 26 | 28 | 30 | 32 | 36 |

| mm | 50 | 65 | 80 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 650 | 700 | 750 | 800 | 900 | |

| L(RF) | in | 7 | 7.5 | 8 | 9 | 15.5 | 18 | 21 | 24 | 27 | 30 | 34 | 36 | 42 | 45 | 49 | 51 | 54 | 60 |

| mm | 178 | 190 | 203 | 229 | 394 | 457 | 533 | 610 | 686 | 762 | 864 | 914 | 1067 | 1143 | 1245 | 1295 | 1372 | 1524 | |

| L1(BW) | in | 8.5 | 9.5 | 11.12 | 12 | 18 | 20.5 | 22 | 25 | 30 | 33 | 36 | 39 | 45 | 49 | 53 | 55 | 60 | 68 |

| mm | 216 | 241 | 283 | 305 | 457 | 521 | 559 | 635 | 762 | 838 | 814 | 991 | 1143 | 1245 | 1346 | 1397 | 1524 | 1727 | |

| H | in | 7 | 7.5 | 8.25 | 9.25 | 20.88 | 24.62 | 25.62 | 30.75 | 31 | 36.25 | 38.25 | 43.38 | 5.25 | 50.75 | 55.12 | 64.12 | 70.88 | 80.75 |

| mm | 177 | 190 | 210 | 235 | 530 | 625 | 650 | 780 | 790 | 920 | 970 | 1100 | 1150 | 1290 | 1400 | 1630 | 1840 | 2050 | |

| W | in | 14 | 16 | 20 | 20 | 24 | 24 | 24 | 24 | 32 | 32 | 32 | 32 | 32 | 32 | 32 | 32 | 32 | 32 |

| mm | 350 | 400 | 500 | 500 | 600 | 600 | 600 | 600 | 800 | 800 | 800 | 800 | 800 | 800 | 800 | 800 | 800 | 800 | |

| WT(Kg) | RF | 15 | 19 | 27 | 38 | 81 | 140 | 160 | 205 | 260 | 390 | 510 | 750 | 1200 | 1400 | 1860 | 2100 | 2530 | 2970 |

| BW | 13.5 | 15.5 | 24.5 | 32.5 | 76 | 132 | 147 | 182 | 241 | 370 | 495 | 726 | 1125 | 1250 | 1640 | 1930 | 2390 | 276 |

| Type | Nominal pressure(MPa) | Testing pressure | Suitable temperature(°C) | Suitable medium | |

| Strength (water) (MPa) | Enclose (Water) (MPa) | ||||

| Q41 /61 H-16C | 1.6 | 2.4 | 1.76 | -40~200ºC | Water,Vapour,Oil |

| Q41 /61 H-25C | 2.5 | 3.75 | 2.5 | ||

Q1:What is the main suitable of this valve?

This product is particularly suitable for media such as steel, aluminum, fiber, small solid particles, pulp, coal ash, petroleum gas, etc.

Q2:What type of seating is used?

Non metallic elastic materials are embedded in the metal seat, and the metal surface of the valve seat is well protected.

Our top mounted eccentric hemispherical valve adopts advanced sealing design to ensure excellent sealing effect under various working conditions, effectively preventing leakage. The full path design allows the fluid to pass through the valve without obstruction, reducing pressure loss and improving the overall efficiency of the system. Made with high-quality materials and subjected to strict processing and precision machining, the valve ensures wear resistance and corrosion resistance, extending its service life.