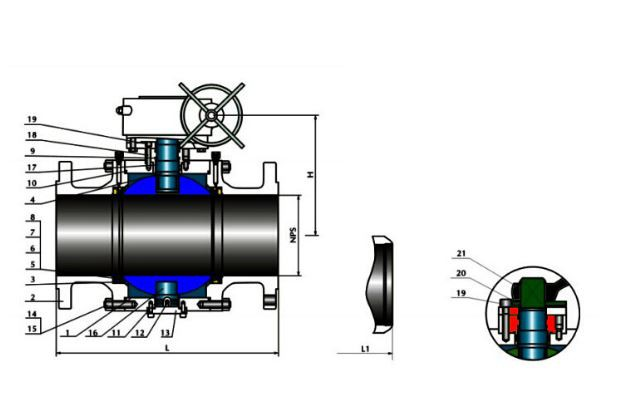

Split body reduce bore trunnion mounted ball valve have two piece and three piece body structure.middle part is bolt connection, RPTFE seal insert into stainless steel ring with spring .keep good sealling...

| Availability: | |

|---|---|

| Quantity: | |

The 3PCS forged steel ball valve represents the latest development in ball valve technology and is suitable for long-distance transportation pipelines and general industrial pipelines. In terms of design, it can withstand the invasion of various corrosive and non corrosive media in harsh environments, ensuring its strength, safety, and precise tolerances. Unlike traditional floating ball valves, this fixed ball valve operates such that the force exerted by fluid pressure on the ball is fully transmitted to the bearing, preventing the ball from moving onto the seat. Therefore, the seat will not bear excessive pressure. This reduces the torque requirement for fixed ball valves, minimizes significant seat deformation, ensures stable sealing performance and long service life, making it particularly suitable for high-pressure and large-diameter applications. Its unique spring-loaded seat assembly has a self tightening function, ensuring upstream sealing effect. Each valve is equipped with two bi-directional sealing seats, with no flow restrictions, and is recommended for horizontal installation.

● Standard Port Design: ensures efficient flow and reduces resistance, making it an ideal choice for achieving uninterrupted fluid regulation in various applications.

● Flexible Connection: Provides options for threading, welding, and flange ends, making it easy to integrate into a variety of piping systems.

● Flow Efficiency: Adopting standard port design can reduce pressure loss, improve flow performance, and ensure smooth operation of pipeline systems.

| No | Part Name | ASTM Material | ||

| Carbon steel | 18Cr-19Ni-2Mo | Low temperature steel | ||

| 1 | Body | A216-WCB | A351-CF8M | A352-LCB |

| 2 | Bonnet | A216-WCB | A351-CF8M | A352-LCB |

| 3 | Ball | A182-F304 | A182-F316 | A182-F314 |

| 4 | Stem | A276-304 | A276-316 | A276-304 |

| 5 | Seat | A105+ENP | A182-F316 | A350-LF2+ENP |

| 6 | Stem insert | Class filled PTFE | A313-304 | |

| 7 | Seat spring | A313-304 | Inconel X-750 | A313-304 |

| 8 | O-ring | NBR | PTFE | PTFE |

| 9 | O-ring | NBR | PTFE | PTFE |

| 10 | Gasket | Graphite+304 | Graphite+316 | Graphite+304 |

| 12 | Spring | A313-304 | A313-316 | A313-304 |

| 13 | Grounding plunger | A216-WCB | A182-F316 | A182-F304 |

| 14 | Stud | A193-B7 | A193-B8 | A320-L7 |

| 15 | Nut | A194-2H | A194 8 | A194 4 |

| 16 | Trunnion | A276-304 | A276-316 | A276-304 |

| 17 | Trunnion bearing | 304+PTFE | 316+PTFE | 304+PTFE |

| 18 | Gland flange | A193-B7 | A193-8 | A193-B7 |

| 19 | Gland bolt | A193-B7 | A193-B8 | A193-B7 |

| 20 | Stop plate | Carbon steel | Carbon steel+Zn | Carbon steel |

| 21 | Handle | Carbon steel | ||

Main Dimensions

| Size | in | 2 | 2 1/2 | 3 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 24 | 26 | 28 | 30 | 32 | 36 |

| mm | 50 | 65 | 80 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 650 | 700 | 750 | 800 | 900 | |

| L(RF) | in | 7 | 7.5 | 8 | 9 | 15.5 | 18 | 21 | 24 | 27 | 30 | 34 | 36 | 42 | 45 | 49 | 51 | 54 | 60 |

| mm | 178 | 190 | 203 | 229 | 394 | 457 | 533 | 610 | 686 | 762 | 864 | 914 | 1067 | 1143 | 1245 | 1295 | 1372 | 1524 | |

| L1(BW) | in | 8.5 | 9.5 | 11.12 | 12 | 18 | 20.5 | 22 | 25 | 30 | 33 | 36 | 39 | 45 | 49 | 53 | 55 | 60 | 68 |

| mm | 216 | 241 | 283 | 305 | 457 | 521 | 559 | 635 | 762 | 838 | 814 | 991 | 1143 | 1245 | 1346 | 1397 | 1524 | 1727 | |

| H | in | 7 | 7.5 | 8.25 | 9.25 | 20.88 | 24.62 | 25.62 | 30.75 | 31 | 36.25 | 38.25 | 43.38 | 5.25 | 50.75 | 55.12 | 64.12 | 70.88 | 80.75 |

| mm | 177 | 190 | 210 | 235 | 530 | 625 | 650 | 780 | 790 | 920 | 970 | 1100 | 1150 | 1290 | 1400 | 1630 | 1840 | 2050 | |

| W | in | 14 | 16 | 20 | 20 | 24 | 24 | 24 | 24 | 32 | 32 | 32 | 32 | 32 | 32 | 32 | 32 | 32 | 32 |

| mm | 350 | 400 | 500 | 500 | 600 | 600 | 600 | 600 | 800 | 800 | 800 | 800 | 800 | 800 | 800 | 800 | 800 | 800 | |

| WT(Kg) | RF | 15 | 19 | 27 | 38 | 81 | 140 | 160 | 205 | 260 | 390 | 510 | 750 | 1200 | 1400 | 1860 | 2100 | 2530 | 2970 |

| BW | 13.5 | 15.5 | 24.5 | 32.5 | 76 | 132 | 147 | 182 | 241 | 370 | 495 | 726 | 1125 | 1250 | 1640 | 1930 | 2390 | 276 |

| TYPE | TRUNNION BALL VALVE | SIZE | 1/2"--48"(DN15--DN1200) |

| STRUCTURE | TRUNNION BALL VALVE | PRESSURE RATING | ANSI CLASS 150--2500(1.6MPa--42.0MPa) |

| CONNECTION | THREADED, WELDED,FLANGE END | FUCTION | BLOW-DOWN VALVE |

| OPERATION | MANUAL,PNEUMATIC,ELECTRIC | APPLICATION | INDUSTRIAL USAGE |

| PRODUCTION CAPACITY | 1000000PCSNEAR | PACKAGE | PLYWOOD CASE |

| WARRANTY PERIOD | 12 MONTHS | TRADE MARK | GOOLE,OEM |

| ORIGIN | WENZHOU ZHEJIANG | HS CODE | 84819090 |

Q:What is the advantage of the Standard Port design?

The standard port design minimizes flow resistance and prevents any turbulence, ensuring smoother and more efficient flow in the pipeline.

Q:How does the valve handle sealing at high pressure?

The valve is equipped with a self releasing seat design, which ensures effective sealing under high pressure, prevents leakage, and reduces operating torque.

Our 3 PCS forged steel ball valves are dedicated to innovation, designed to reduce wear, ensure operational reliability, and achieve effective fluid control. By adopting an earshaft mounting design and standard port configuration, our valves perform well in high demand applications. Our team is committed to providing customized solutions to ensure that your specific needs are accurately and professionally met.