Specifications.1.Design and manufacture conform to API 6D.2.Face to face length conforms to ASME B16.10...

| Availability: | |

|---|---|

| Quantity: | |

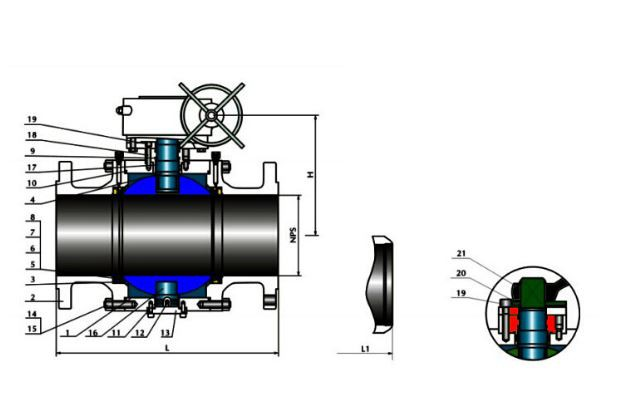

3 PCS ball valves are designed according to API 6D for ASME1503006009001500 and 2500 grades. The valve body and seal are connected by cast steel and three forged steel side inlet design bolts, ear shaft bolts, and the valve body thickness complies with ANSI B16.34. The valve seat ring is floating and equipped with springs to ensure contact with the ball, providing effective tight sealing even in low pressure differentials between the chamber and downstream seals. The standard design is a soft seat. We can provide different soft seat materials according to the customer's working conditions. Provide sufficient and reduced holes. According to customer requirements, electric, pneumatic, and hydraulic actuators can be provided.

●Metal-to-Metal Seats: The valve seat is designed for high pressure conditions to ensure excellent sealing and durability in harsh conditions.

●Full-Bore and Reduced-Bore Options: Provides flexibility in flow control for various pipeline applications.

| No | Part Name | ASTM Material | ||

| Carbon steel | 18Cr-19Ni-2Mo | Low temperature steel | ||

| 1 | Body | A216-WCB | A351-CF8M | A352-LCB |

| 2 | Bonnet | A216-WCB | A351-CF8M | A352-LCB |

| 3 | Ball | A182-F304 | A182-F316 | A182-F314 |

| 4 | Stem | A276-304 | A276-316 | A276-304 |

| 5 | Seat | A105+ENP | A182-F316 | A350-LF2+ENP |

| 6 | Stem insert | Class filled PTFE | A313-304 | |

| 7 | Seat spring | A313-304 | Inconel X-750 | A313-304 |

| 8 | O-ring | NBR | PTFE | PTFE |

| 9 | O-ring | NBR | PTFE | PTFE |

| 10 | Gasket | Graphite+304 | Graphite+316 | Graphite+304 |

| 12 | Spring | A313-304 | A313-316 | A313-304 |

| 13 | Grounding plunger | A216-WCB | A182-F316 | A182-F304 |

| 14 | Stud | A193-B7 | A193-B8 | A320-L7 |

| 15 | Nut | A194-2H | A194 8 | A194 4 |

| 16 | Trunnion | A276-304 | A276-316 | A276-304 |

| 17 | Trunnion bearing | 304+PTFE | 316+PTFE | 304+PTFE |

| 18 | Gland flange | A193-B7 | A193-8 | A193-B7 |

| 19 | Gland bolt | A193-B7 | A193-B8 | A193-B7 |

| 20 | Stop plate | Carbon steel | Carbon steel+Zn | Carbon steel |

| 21 | Handle | Carbon steel | ||

Main Dimensions

| Size | in | 2 | 2 1/2 | 3 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 24 | 26 | 28 | 30 | 32 | 36 |

| mm | 50 | 65 | 80 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 650 | 700 | 750 | 800 | 900 | |

| L(RF) | in | 7 | 7.5 | 8 | 9 | 15.5 | 18 | 21 | 24 | 27 | 30 | 34 | 36 | 42 | 45 | 49 | 51 | 54 | 60 |

| mm | 178 | 190 | 203 | 229 | 394 | 457 | 533 | 610 | 686 | 762 | 864 | 914 | 1067 | 1143 | 1245 | 1295 | 1372 | 1524 | |

| L1(BW) | in | 8.5 | 9.5 | 11.12 | 12 | 18 | 20.5 | 22 | 25 | 30 | 33 | 36 | 39 | 45 | 49 | 53 | 55 | 60 | 68 |

| mm | 216 | 241 | 283 | 305 | 457 | 521 | 559 | 635 | 762 | 838 | 814 | 991 | 1143 | 1245 | 1346 | 1397 | 1524 | 1727 | |

| H | in | 7 | 7.5 | 8.25 | 9.25 | 20.88 | 24.62 | 25.62 | 30.75 | 31 | 36.25 | 38.25 | 43.38 | 5.25 | 50.75 | 55.12 | 64.12 | 70.88 | 80.75 |

| mm | 177 | 190 | 210 | 235 | 530 | 625 | 650 | 780 | 790 | 920 | 970 | 1100 | 1150 | 1290 | 1400 | 1630 | 1840 | 2050 | |

| W | in | 14 | 16 | 20 | 20 | 24 | 24 | 24 | 24 | 32 | 32 | 32 | 32 | 32 | 32 | 32 | 32 | 32 | 32 |

| mm | 350 | 400 | 500 | 500 | 600 | 600 | 600 | 600 | 800 | 800 | 800 | 800 | 800 | 800 | 800 | 800 | 800 | 800 | |

| WT(Kg) | RF | 15 | 19 | 27 | 38 | 81 | 140 | 160 | 205 | 260 | 390 | 510 | 750 | 1200 | 1400 | 1860 | 2100 | 2530 | 2970 |

| BW | 13.5 | 15.5 | 24.5 | 32.5 | 76 | 132 | 147 | 182 | 241 | 370 | 495 | 726 | 1125 | 1250 | 1640 | 1930 | 2390 | 276 |

| TYPE | TRUNNION BALL VALVE | SIZE | 1/2"--48"(DN15--DN1200) |

| STRUCTURE | TRUNNION BALL VALVE | PRESSURE RATING | ANSI CLASS 150--2500(1.6MPa--42.0MPa) |

| CONNECTION | THREADED, WELDED,FLANGE END | FUCTION | BLOW-DOWN VALVE |

| OPERATION | MANUAL,PNEUMATIC,ELECTRIC | APPLICATION | INDUSTRIAL USAGE |

| PRODUCTION CAPACITY | 1000000PCSNEAR | PACKAGE | PLYWOOD CASE |

| WARRANTY PERIOD | 12 MONTHS | TRADE MARK | GOOLE,OEM |

| ORIGIN | WENZHOU ZHEJIANG | HS CODE | 84819090 |

Q:What are the seat options available for this valve?

The valve is available with metal-to-metal seats for high-pressure applications, and soft seat materials can be chosen based on the fluid type and operational conditions.

Q:What is the maximum pressure this valve can handle?

The valve is designed for high-pressure systems, with a pressure rating of up to ANSI Class 2500, suitable for demanding pipeline applications.

Q:Can this valve be used in large pipelines?

Yes, this valve is specifically designed for large-size pipelines, providing reliable fluid control and isolation in systems with large diameters and high fluid volumes.

The high-pressure forged metal seat ear ball valve used for pipeline services is designed to provide safe and efficient fluid control for large-diameter high-pressure pipeline systems. With its metal to metal seat, ear shaft mounting ball design, and customizable functionality, this valve ensures reliable performance and sealing even under the most demanding conditions. Whether you need manual, pneumatic, or electric drive, our team will work with you to tailor solutions to meet your specific needs, ensuring that your pipeline system has optimal performance and reliability.