Specifications.1.Design and manufacture conform to API 6D.2.Face to face length conforms to ASME B16.10...

| Availability: | |

|---|---|

| Quantity: | |

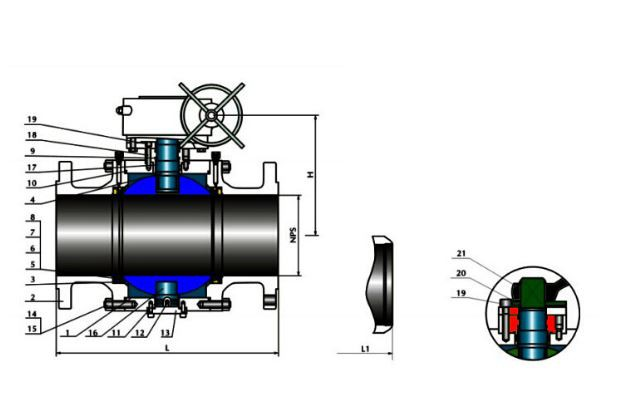

The three-piece ball valve has two three-piece structures, the middle part is bolted, and the RPTFE seal is embedded in the stainless steel spiral spring to maintain good sealing. The three valve bodies were designed following the API 6D standard. The stem design has antistatic and antiblowing function. The seat design ensures a perfect sealing effect, available as a self-relief or double piston effect type. The design reduces friction and achieving a smaller working torque. Double blocking and deflation can be performed to allow expulsion and discharge of fluid from the body chamber. Suitable for adequate and reduced holes. Fire testing as per BSEN12266-2, API6FA and API 607 standards. Electric, pneumatic and hydraulic actuators are available upon customer request.

●Metal-to-Metal Seats: The seats are designed in high pressure environments to ensure excellent sealing and durability under harsh conditions.

●Full-Bore and Reduced-Bore Options: Provides flexibility in flow control for various pipeline applications.

| No | Part Name | ASTM Material | ||

| Carbon steel | 18Cr-19Ni-2Mo | Low temperature steel | ||

| 1 | Body | A216-WCB | A351-CF8M | A352-LCB |

| 2 | Bonnet | A216-WCB | A351-CF8M | A352-LCB |

| 3 | Ball | A182-F304 | A182-F316 | A182-F314 |

| 4 | Stem | A276-304 | A276-316 | A276-304 |

| 5 | Seat | A105+ENP | A182-F316 | A350-LF2+ENP |

| 6 | Stem insert | Class filled PTFE | A313-304 | |

| 7 | Seat spring | A313-304 | Inconel X-750 | A313-304 |

| 8 | O-ring | NBR | PTFE | PTFE |

| 9 | O-ring | NBR | PTFE | PTFE |

| 10 | Gasket | Graphite+304 | Graphite+316 | Graphite+304 |

| 12 | Spring | A313-304 | A313-316 | A313-304 |

| 13 | Grounding plunger | A216-WCB | A182-F316 | A182-F304 |

| 14 | Stud | A193-B7 | A193-B8 | A320-L7 |

| 15 | Nut | A194-2H | A194 8 | A194 4 |

| 16 | Trunnion | A276-304 | A276-316 | A276-304 |

| 17 | Trunnion bearing | 304+PTFE | 316+PTFE | 304+PTFE |

| 18 | Gland flange | A193-B7 | A193-8 | A193-B7 |

| 19 | Gland bolt | A193-B7 | A193-B8 | A193-B7 |

| 20 | Stop plate | Carbon steel | Carbon steel+Zn | Carbon steel |

| 21 | Handle | Carbon steel | ||

Main Dimensions

| Size | in | 2 | 2 1/2 | 3 | 4 | 6 | 8 | 10 | 12 | 14 | 16 | 18 | 20 | 24 | 26 | 28 | 30 | 32 | 36 |

| mm | 50 | 65 | 80 | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 450 | 500 | 600 | 650 | 700 | 750 | 800 | 900 | |

| L(RF) | in | 7 | 7.5 | 8 | 9 | 15.5 | 18 | 21 | 24 | 27 | 30 | 34 | 36 | 42 | 45 | 49 | 51 | 54 | 60 |

| mm | 178 | 190 | 203 | 229 | 394 | 457 | 533 | 610 | 686 | 762 | 864 | 914 | 1067 | 1143 | 1245 | 1295 | 1372 | 1524 | |

| L1(BW) | in | 8.5 | 9.5 | 11.12 | 12 | 18 | 20.5 | 22 | 25 | 30 | 33 | 36 | 39 | 45 | 49 | 53 | 55 | 60 | 68 |

| mm | 216 | 241 | 283 | 305 | 457 | 521 | 559 | 635 | 762 | 838 | 814 | 991 | 1143 | 1245 | 1346 | 1397 | 1524 | 1727 | |

| H | in | 7 | 7.5 | 8.25 | 9.25 | 20.88 | 24.62 | 25.62 | 30.75 | 31 | 36.25 | 38.25 | 43.38 | 5.25 | 50.75 | 55.12 | 64.12 | 70.88 | 80.75 |

| mm | 177 | 190 | 210 | 235 | 530 | 625 | 650 | 780 | 790 | 920 | 970 | 1100 | 1150 | 1290 | 1400 | 1630 | 1840 | 2050 | |

| W | in | 14 | 16 | 20 | 20 | 24 | 24 | 24 | 24 | 32 | 32 | 32 | 32 | 32 | 32 | 32 | 32 | 32 | 32 |

| mm | 350 | 400 | 500 | 500 | 600 | 600 | 600 | 600 | 800 | 800 | 800 | 800 | 800 | 800 | 800 | 800 | 800 | 800 | |

| WT(Kg) | RF | 15 | 19 | 27 | 38 | 81 | 140 | 160 | 205 | 260 | 390 | 510 | 750 | 1200 | 1400 | 1860 | 2100 | 2530 | 2970 |

| BW | 13.5 | 15.5 | 24.5 | 32.5 | 76 | 132 | 147 | 182 | 241 | 370 | 495 | 726 | 1125 | 1250 | 1640 | 1930 | 2390 | 276 |

| TYPE | TRUNNION BALL VALVE | SIZE | 1/2"--48"(DN15--DN1200) |

| STRUCTURE | TRUNNION BALL VALVE | PRESSURE RATING | ANSI CLASS 150--2500(1.6MPa--42.0MPa) |

| CONNECTION | THREADED, WELDED,FLANGE END | FUCTION | BLOW-DOWN VALVE |

| OPERATION | MANUAL,PNEUMATIC,ELECTRIC | APPLICATION | INDUSTRIAL USAGE |

| PRODUCTION CAPACITY | 1000000PCSNEAR | PACKAGE | PLYWOOD CASE |

| WARRANTY PERIOD | 12 MONTHS | TRADE MARK | GOOLE,OEM |

| ORIGIN | WENZHOU ZHEJIANG | HS CODE | 84819090 |

Q:What is the advantage of the Standard Port design?

The standard port is designed to minimize flow resistance and prevent any turbulence, thus ensuring a smoother and more efficient flow in the pipeline.

Q:How does the valve handle sealing at high pressure?

The valve uses high strength and corrosion resistant materials to enhance its durability and service life. The precision manufacturing technology of the valve ensures its sealing effect and control of the fluid, enabling it to adapt to a variety of harsh working environments and media.

Innovative concept through 3 PCS ball valve design to achieve effective fluid control, reduce wear and ensure operational reliability. With carefully designed and standardized port configurations, our valves demonstrate superior performance in high-demand applications. Our team focuses on providing customized solutions to ensure precision and professionalism to meet your specific needs.