Side entry type stainless steel floating ball valve main parameterNormal Size: 1/2"~8"Pressure rating: 150 LB~900 LBMaterials: WCB, LCB, LCC, CF8...

| Availability: | |

|---|---|

| Quantity: | |

A forged steel two-piece ball valve designed specifically for high-pressure pipelines, aimed at achieving stable flow control. Its unique side entry two-piece design makes maintenance easier. In addition, forged steel enhances its mechanical strength and structural integrity. This valve can be rotated 90 degrees for quick switching, making it suitable for systems that require medium isolation, diversion, or directional control. The installation of flanges ensures the safety and reliability of valves, perfectly adapting to environments with high reliability and safety requirements.

● Side-Entry Structure: The valve body design allows maintenance from the side, and internal parts can be easily replaced without having to remove the entire valve from the pipe.

● One-Piece Forged Body: Compared with the structure of castings, its strength is significantly improved, and its disadvantages are greatly reduced, ensuring long-term stable mechanical properties.

● Quick 90° Operation: Supports fast shutdown or switching functions, making it an ideal choice for time-sensitive application scenarios.

| No | Part Name | ASTM Material | ||

| Carbon steel | 18Cr-9Ni-2Mo | Low temp steel | ||

| 1 | Body | A105 | A182-F316 | A350-LF2 |

| 2 | Bonnet | A105 | A182-F316 | A350-LF2 |

| 3 | Ball | A182-F304 | A182-F316 | A182-F304 |

| 4 | Stem | A276-304 | A276-316 | A276-304 |

| 5 | Seat ring | R.PTFE | ||

| 6 | Gasket | Graphite+304 | PTFE | Graphite+304 |

| 7 | Stud | A193-B7 | A193-B8 | A320-L7 |

| 8 | Nut | A194-2H | A194-8 | A194-4 |

| 9 | Packing | PTFE | ||

| 10 | Gland | A105 | A182-F316 | A350-LF2 |

| 11 | Gland bolt | A193-B7 | A193-B8 | A193-B7 |

| 12 | Stop plate | Carbon steel | Carbon steel+Zn | Carbon steel |

| 13 | Handle | Carbon steel | ||

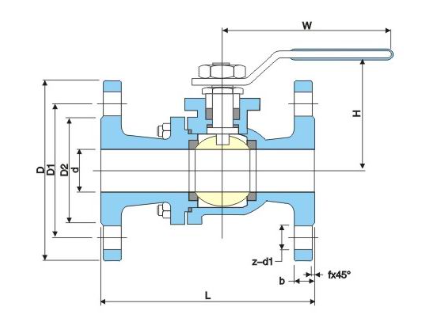

Main Dimensions

| Size | in | 1/2 | 3/4 | 1 | 1 1/2 | 2 | 2 1/2 | 3 | 4 | 6 | 8 | 10 | 12 |

| mm | 15 | 20 | 25 | 40 | 50 | 65 | 80 | 100 | 150 | 200 | 250 | 300 | |

| L(RF) | in | 4.25 | 4.62 | 5.00 | 6.50 | 7.00 | 7.50 | 8.00 | 9.00 | 15.50 | 18.00 | 21.00 | / |

| mm | 108 | 117 | 127 | 165 | 178 | 190 | 203 | 229 | 394 | 457 | 533 | / | |

| L1(BW) | in | 5.50 | 6.00 | 6.50 | 7.50 | 8.50 | 9.50 | 11.12 | 12.00 | 18.00 | 20.50 | 22.00 | / |

| mm | 140 | 152 | 165 | 190 | 216 | 241 | 283 | 305 | 457 | 521 | 559 | / | |

| H | in | 2.12 | 2.12 | 2.50 | 3.38 | 4.00 | 6.00 | 7.00 | 9.25 | 9.88 | 11.00 | 12.62 | / |

| mm | 55 | 55 | 65 | 85 | 100 | 150 | 180 | 235 | 250 | 280 | 320 | / | |

| W | in | 8 | 8 | 12 | 12 | 16 | 16 | 24 | 24 | 24 | 24 | 32 | / |

| mm | 200 | 200 | 300 | 300 | 400 | 400 | 600 | 600 | 600 | 600 | 800 | / | |

| WT(Kg) | RF | 3.1 | 4.1 | 6 | 9.5 | 12.8 | 20 | 26 | 45 | 126 | 216 | 270 | / |

| BW | 2.6 | 3.9 | 5.2 | 8.7 | 11.8 | 19 | 28 | 47 | 131 | 226 | 295 | / |

| Nominal pressure | PN1.6~6.4MPa |

| Nominal diameter | 15-300mm |

| The inherent flow characteristics | quick opening |

| Appliable Temperature | Hard Seal:-40~300ºC |

| Soft Seal | -40~180ºC |

| Applicable medium | Water,gas,oil quality and so on. |

| Driving Means | Manual ,Electric, Worm wheels, Pneumatic |

| Flange Type | ANSI, JIS, DIN, GB/T 9113, JB/T 79 |

| Body materials | WCB, CF8, CF8M, CF3M |

| Stem | 2Cr13, 304, 316 |

| Valve Seat | PTFE, 0Crl7Ni4Cu4Nb |

| Core Material | CF8, CF8M, CF3M. |

| Ball Type | DN200 and below sizes----Floating Ball DN200 and above sizes----Trunnion Ball |

Q1: What makes the side-entry structure beneficial?

A: It allows for easy internal maintenance without removing the valve from the line, reducing downtime and service complexity.

Q2: Is this valve suitable for automation?

A: Yes, the valve supports manual, pneumatic, and electric actuation for flexible control options.

We have developed a robust two-piece forged steel ball valve that not only has excellent durability, but also integrates intelligent maintenance, automation compatibility, and reliable sealing performance in pressure environments. This valve has a side inlet, an automatic seat compensation float, and a forged steel structure, providing stable and reliable performance under various complex working conditions. Whether used for closing, switching, or flow distribution, the design of this valve ensures smooth and efficient operation of the system.