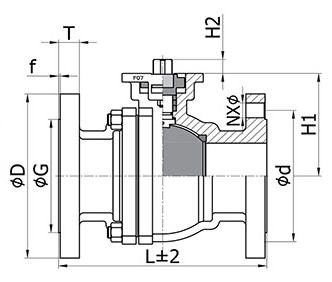

Side entry type stainless steel floating ball valve main parameterNormal Size: 1/2"~8"Pressure rating: 150 LB~900 LBMaterials: WCB, LCB, LCC, CF8...

| Availability: | |

|---|---|

| Quantity: | |

The Q41F-16T ball valve features a 90-degree rotation action, similar to that of other valves. However, its distinctiveness is found in its spherical valve body, which contains circular holes or channels. Ball valves are primarily utilized to shut off, distribute, and redirect flow within pipelines. They necessitate only a 90-degree rotation and minimal rotational force to achieve a secure seal.

● Fire-Safe Design: Valves equipped with a fire protection design can maintain their integrity and functionality in the event of a fire.

● Anti-Static Devices: These devices help reduce the risk of fires and ensure a safe operating environment by dissipating any static electricity safely.

● Low Emission Control: Low emission control valves are engineered to minimize the release of harmful gases or vapors into the atmosphere.

| Size | in | 1/2 | 3/4 | 1 | 1 1/2 | 2 | 2 1/2 | 3 | 4 | 6 | 8 | 10 | 12 |

| mm | 15 | 20 | 25 | 40 | 50 | 65 | 80 | 100 | 150 | 200 | 250 | 300 | |

| L(RF) | in | 4.25 | 4.62 | 5.00 | 6.50 | 7.00 | 7.50 | 8.00 | 9.00 | 15.50 | 18.00 | 21.00 | / |

| mm | 108 | 117 | 127 | 165 | 178 | 190 | 203 | 229 | 394 | 457 | 533 | / | |

| L1(BW) | in | 5.50 | 6.00 | 6.50 | 7.50 | 8.50 | 9.50 | 11.12 | 12.00 | 18.00 | 20.50 | 22.00 | / |

| mm | 140 | 152 | 165 | 190 | 216 | 241 | 283 | 305 | 457 | 521 | 559 | / | |

| H | in | 2.12 | 2.12 | 2.75 | 3.50 | 4.12 | 6.12 | 7.25 | 8.00 | 10.00 | 11.00 | 13.50 | / |

| mm | 55 | 55 | 70 | 90 | 105 | 155 | 185 | 205 | 255 | 280 | 345 | / | |

| W | in | 5 | 5 | 6 | 8 | 14 | 16 | 20 | 20 | 24 | 32 | 32 | / |

| mm | 130 | 130 | 160 | 200 | 350 | 400 | 500 | 500 | 600 | 800 | 800 | / | |

| WT(Kg) | RF | 2.3 | 3 | 4.5 | 7 | 9.5 | 15 | 19 | 33 | 93 | 160 | 200 | / |

| BW | 1.8 | 2.8 | 3.7 | 6.2 | 8.5 | 14 | 21 | 35 | 98 | 170 | 225 | / |

| Size | 1/2"~12" |

| Pressure rating | 150LB/300LB/600LB |

| Body material | Carbon steel,stainless steel or other material |

| Trim material | CS+ENP,13Cr,F304,F316,INCONEL,MONEL,DUPLEX.,etc |

| Driving modes | Lever,Gear,Pneumatic,Electric |

Q1: What makes the side-entry structure beneficial?

A: It allows for easy internal maintenance without removing the valve from the line, reducing downtime and service complexity.

Q2: Is this valve suitable for automation?

A: Yes, the valve supports manual, pneumatic, and electric actuation for flexible control options.

We select high-quality brass as the primary material to guarantee the strength and corrosion resistance of the valve, thereby extending its lifespan. By integrating modern precision casting and machining technologies, each valve is subjected to rigorous quality control to ensure its sealing capabilities and smooth functioning. We provide a variety of sizes, pressure ratings, and temperature ratings to cater to the requirements of diverse industrial applications.