Flange connection Cryogenic ball valve is used for low temperature working condition,especially for some hazard media, such as liquidized natural gas. Applied to LNG plant, LNG receiving station, LNG gasification station and LNG carrier and ship...

| Availability: | |

|---|---|

| Quantity: | |

The flange connected low-temperature ball valve is suitable for low-temperature working conditions, especially for hazardous media such as liquefied natural gas. Suitable for LNG factories, LNG receiving stations, LNG gasification stations, as well as LNG transport ships and vessels.

● Cryogenic Design: This valve is designed specifically for low-temperature applications, ensuring consistent and reliable performance when handling liquefied gases and other cold materials in low-temperature environments.

● Metal-Seated: The metal valve seat is designed to provide reliable sealing at extreme temperatures, ensuring leak free operation under challenging low temperature conditions.

● Reliable Performance in Hazardous Media: This valve is designed specifically for handling hazardous and flammable media such as liquefied natural gas, ensuring the safety of critical operations.

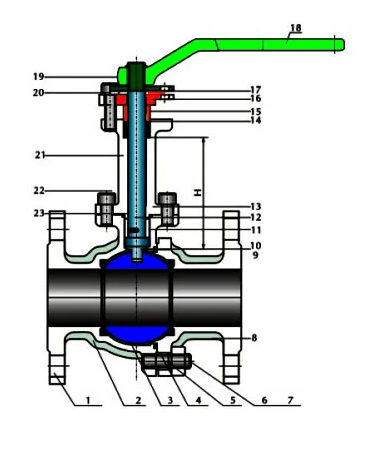

| No | Part Name | Materials | |

| -46°C~-101°C~-196°C | |||

| 1 | Left Body | A352-LCB,LCC,LC3,A351-CF8,A351-CF8M | |

| 2 | Seat | PTFE,RPTFE,PEEK,PPL,POM,KARBATE | |

| NYLON,MOLON,DEVLON | |||

| 3 | Ball | A182-F304,F316 | |

| 4 | O-ring | VITON | |

| 5 | Gasket | Flexible graphite+304,flexible graphite+316,PTFE | |

| 6 | Bolt | A194-4,8,8M | |

| 7 | Nut | A320-L7,A193-B8,B8M | |

| 8 | Right body | A352-LCB,LCC,LC3,A351-CF8,CF8M | |

| 9 | Spring | ss304,316 | |

| 10 | Small ball | PTFE | |

| 11 | Thrust washer | A182-F6,F316,F316 | |

| 12 | Stem | Flexible graphite,PTFE | |

| 13 | Gasket | A182 F6,F304,F316 | |

| 14 | Packing | A352 LCB,A351 CF8 | |

| 15 | Gland | 1025,stainless steel | |

| 16 | Gland flange | A216 WCB | |

| 17 | Stop plate | 1025 | |

| 18 | Lever | 1035,stainless steel | |

| 19 | Screw | A352-LCB,LCC,LC3,A351-CF8,CF8M | |

| 20 | Screw | 1035,stainless steel | |

| 21 | Extended bonnet | A352-LCB,LCC,LC3,A351-CF8,CF8M, | |

| 22 | Screw | 1035,stainless steel | |

| 23 | Bushing | A182-F6,F304,F316 | |

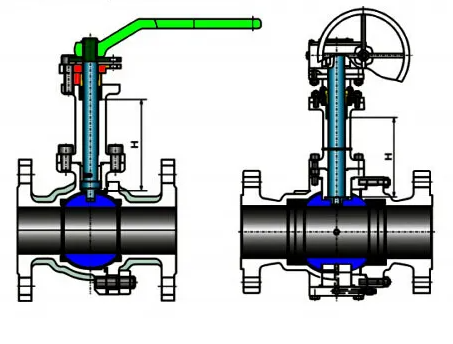

Main Dimensions

| Size(in) | H | ||

| -46°C | -101°C | -196°C | |

| 1/2 | 90 | 110 | 130 |

| 3/4 | 100 | 110 | 140 |

| 1 | 100 | 120 | 150 |

| 1 1/2 | 110 | 130 | 160 |

| 2 | 110 | 130 | 170 |

| 3 | 120 | 150 | 190 |

| 4 | 130 | 160 | 200 |

| 6 | 140 | 170 | 220 |

| 8 | 140 | 170 | 220 |

| 10 | 150 | 180 | 240 |

| 12 | 150 | 180 | 240 |

| 14 | 160 | 190 | 250 |

| 16 | 160 | 190 | 250 |

| 18 | 160 | 190 | 250 |

| 20 | 170 | 200 | 260 |

| 24 | 170 | 200 | 260 |

| Nominal diameter | DN15- DN250 |

| Nominal pressure | 150LB- 300LB |

| Working temperature | -196 - +29ºC |

| Driving means | handle, electric actuator |

| Material | Stainless steel, Forged Steel , LCC/LCB, CF8/CFM8 |

Q1:What is the main use of this valve?

This valve is ideal for cryogenic applications, especially for handling liquefied gases such as LNG, in low-temperature environments.

Q2:What type of seating is used?

It uses a metal seat, designed to maintain reliable sealing performance at extreme low temperatures.

Our forged steel low-temperature metal seat float ball valve is designed specifically for low-temperature applications and has excellent performance in low-temperature environments. The metal seat design of this valve ensures leak proof and reliable sealing even under extreme cold conditions, while its forged steel structure provides strength. It is specifically designed for long-term and reliable handling of liquefied gases and other low-temperature materials.