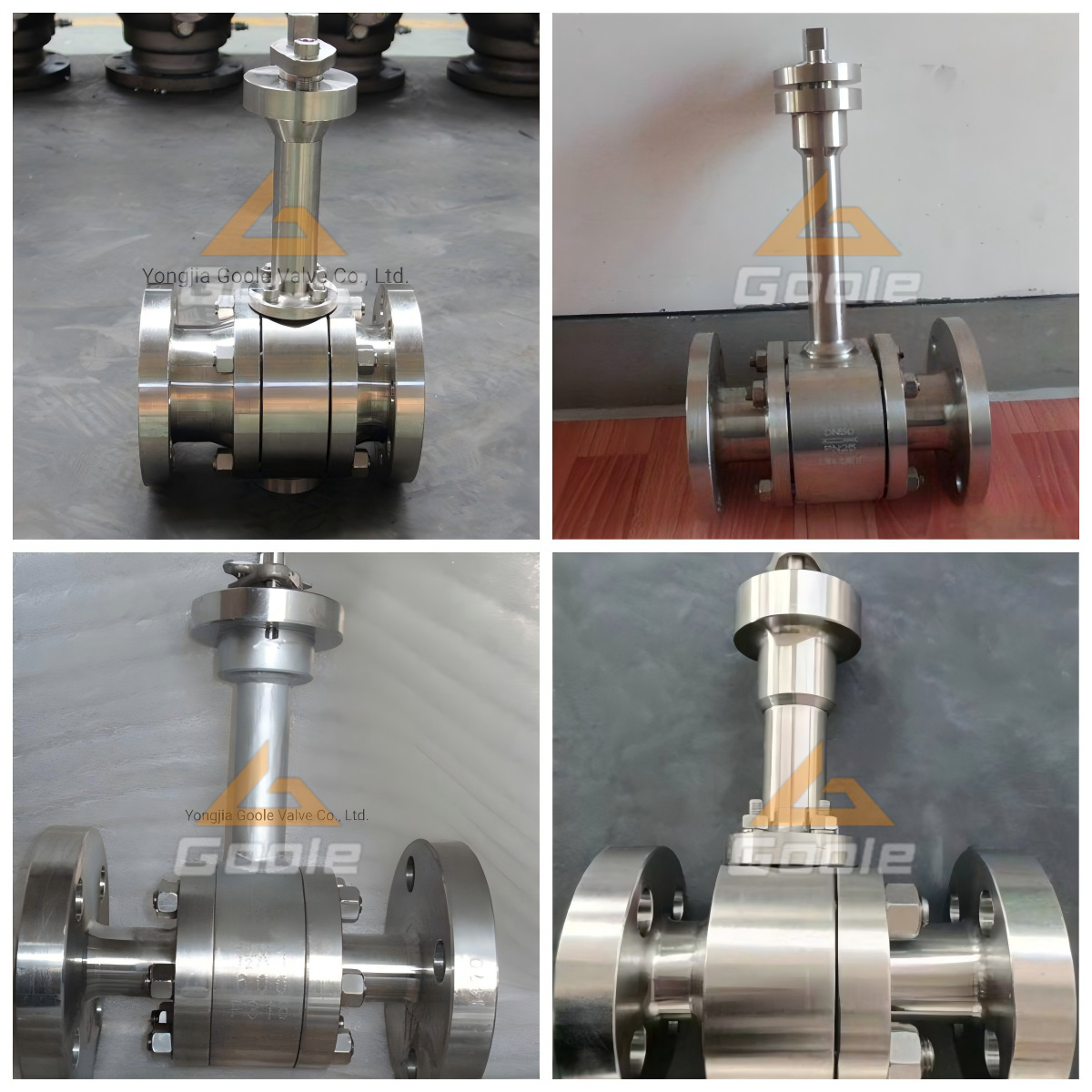

The Forged Steel Cryogenic Metal Seated Floating Ball Valve is built for low-temperature applications, offering reliable sealing for liquefied gases. Its forged steel construction ensures durability and strength in cryogenic conditions.

| Availability: | |

|---|---|

| Quantity: | |

The Forged Steel Cryogenic Metal Seated Floating Ball Valve is specifically designed to perform efficiently in extreme low-temperature environments. Featuring a metal-seated design, it ensures reliable sealing, making it ideal for handling liquefied gases such as LNG (Liquefied Natural Gas) and other cold materials in cryogenic conditions. With a robust forged steel construction, this valve is built for strength and durability, ensuring long-lasting performance even under challenging conditions such as LNG plants, LNG receiving stations, gasification stations, and LNG carriers.

● Cryogenic Design: Engineered for low-temperature applications, the valve ensures consistent and reliable performance in cryogenic environments, handling liquefied gases and other cold materials.

● Metal-Seated: The metal-seated design provides a reliable seal at extreme temperatures, ensuring leak-proof operation under challenging cryogenic conditions.

● Reliable Performance in Hazardous Media: Specifically designed to handle hazardous and flammable media such as LNG, ensuring safety in critical operations.

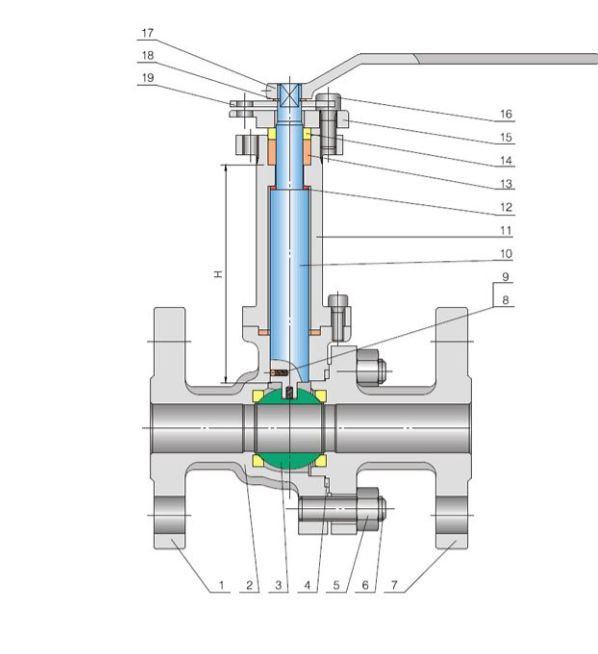

| No | Part Name | Materials | |

| -46°C~-101°C~-196°C | |||

| 1 | Left Body | A352-LCB,LCC,LC3,A351-CF8,A351-CF8M | |

| 2 | Seat | PTFE,RPTFE,PEEK,PPL,POM,KARBATE | |

| NYLON,MOLON,DEVLON | |||

| 3 | Ball | A182-F304,F316 | |

| 4 | O-ring | VITON | |

| 5 | Gasket | Flexible graphite+304,flexible graphite+316,PTFE | |

| 6 | Bolt | A194-4,8,8M | |

| 7 | Nut | A320-L7,A193-B8,B8M | |

| 8 | Right body | A352-LCB,LCC,LC3,A351-CF8,CF8M | |

| 9 | Spring | ss304,316 | |

| 10 | Small ball | PTFE | |

| 11 | Thrust washer | A182-F6,F316,F316 | |

| 12 | Stem | Flexible graphite,PTFE | |

| 13 | Gasket | A182 F6,F304,F316 | |

| 14 | Packing | A352 LCB,A351 CF8 | |

| 15 | Gland | 1025,stainless steel | |

| 16 | Gland flange | A216 WCB | |

| 17 | Stop plate | 1025 | |

| 18 | Lever | 1035,stainless steel | |

| 19 | Screw | A352-LCB,LCC,LC3,A351-CF8,CF8M | |

| 20 | Screw | 1035,stainless steel | |

| 21 | Extended bonnet | A352-LCB,LCC,LC3,A351-CF8,CF8M, | |

| 22 | Screw | 1035,stainless steel | |

| 23 | Bushing | A182-F6,F304,F316 | |

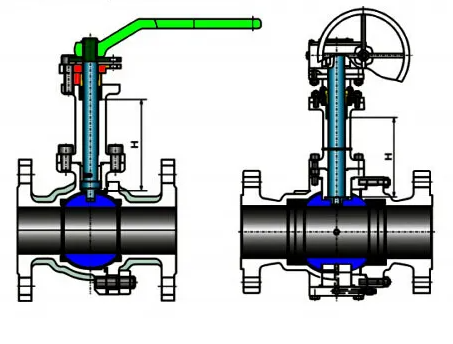

| Size(in) | H | ||

| -46°C | -101°C | -196°C | |

| 1/2 | 90 | 110 | 130 |

| 3/4 | 100 | 110 | 140 |

| 1 | 100 | 120 | 150 |

| 1 1/2 | 110 | 130 | 160 |

| 2 | 110 | 130 | 170 |

| 3 | 120 | 150 | 190 |

| 4 | 130 | 160 | 200 |

| 6 | 140 | 170 | 220 |

| 8 | 140 | 170 | 220 |

| 10 | 150 | 180 | 240 |

| 12 | 150 | 180 | 240 |

| 14 | 160 | 190 | 250 |

| 16 | 160 | 190 | 250 |

| 18 | 160 | 190 | 250 |

| 20 | 170 | 200 | 260 |

| 24 | 170 | 200 | 260 |

| Valve body, side cover | Hastelloy C-276 |

| Sphere Ball | Hastelloy C-276 + cobalt base + tungsten carbide |

| Valve seat | Hastelloy C-276 + cobalt base + tungsten carbide; (Hastelloy G30 for ball valves) |

| Stem | XM-19 |

| Spring | Inconel X-750 |

| Fastener | B7+ fluorine spray |

| Middle flange sealing material | graphite + O-ring (fluorine rubber) |

Q1:What is the main use of this valve?

This valve is ideal for cryogenic applications, especially for handling liquefied gases such as LNG, in low-temperature environments.

Q2:What type of seating is used?

It uses a metal seat, designed to maintain reliable sealing performance at extreme low temperatures.

Our Forged Steel Cryogenic Metal Seated Floating Ball Valve for Low-Temperature Applications offers exceptional performance in cryogenic environments. The valve's metal-seated design ensures a leak-proof, reliable seal under extreme cold conditions, while the forged steel construction provides strength. It is designed to handle liquefied gases and other cryogenic materials with long-term reliability.