Side entry type stainless steel floating ball valve main parameterNormal Size: 1/2"~8"Pressure rating: 150 LB~900 LBMaterials: WCB, LCB, LCC, CF8...

| Availability: | |

|---|---|

| Quantity: | |

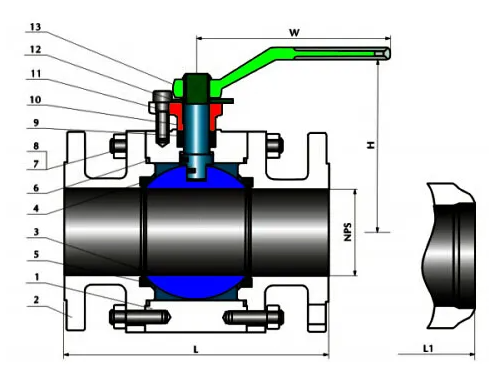

The Q41F ball valve performs a 90 degree rotation operation. Its uniqueness lies in the design of the valve core as a spherical body with a circular channel inside. This type of ball valve is mainly used in pipeline systems to achieve cutting, distribution, and regulation of fluid flow. By rotating only 90 degrees and applying minimal torque, the ball valve can achieve a tight closing effect.

● Fire Safe Design: Valves with fire-resistant structures can maintain their structural and functional integrity in the event of a fire.

● Anti-Static Device: These devices help reduce the possibility of fire and maintain a safe operating environment by ensuring the safe release of static electricity.

● Low Emission Control:Valves designed to minimize the release of harmful gases or vapors into the atmosphere, with the aim of minimizing emissions to the greatest extent possible.

| No | Part Name | ASTM Material | ||

| Carbon steel | 18Cr-9Ni-2Mo | Low temp steel | ||

| 1 | Body | A105 | A182-F316 | A350-LF2 |

| 2 | Bonnet | A105 | A182-F316 | A350-LF2 |

| 3 | Ball | A182-F304 | A182-F316 | A182-F304 |

| 4 | Stem | A276-304 | A276-316 | A276-304 |

| 5 | Seat ring | R.PTFE | ||

| 6 | Gasket | Graphite+304 | PTFE | Graphite+304 |

| 7 | Stud | A193-B7 | A193-B8 | A320-L7 |

| 8 | Nut | A194-2H | A194-8 | A194-4 |

| 9 | Packing | PTFE | ||

| 10 | Gland | A105 | A182-F316 | A350-LF2 |

| 11 | Gland bolt | A193-B7 | A193-B8 | A193-B7 |

| 12 | Stop plate | Carbon steel | Carbon steel+Zn | Carbon steel |

| 13 | Handle | Carbon steel | ||

Main Dimensions

| Size | in | 1/2 | 3/4 | 1 | 1 1/2 | 2 | 2 1/2 | 3 | 4 | 6 | 8 | 10 | 12 |

| mm | 15 | 20 | 25 | 40 | 50 | 65 | 80 | 100 | 150 | 200 | 250 | 300 | |

| L(RF) | in | 4.25 | 4.62 | 5.00 | 6.50 | 7.00 | 7.50 | 8.00 | 9.00 | 15.50 | 18.00 | 21.00 | / |

| mm | 108 | 117 | 127 | 165 | 178 | 190 | 203 | 229 | 394 | 457 | 533 | / | |

| L1(BW) | in | 5.50 | 6.00 | 6.50 | 7.50 | 8.50 | 9.50 | 11.12 | 12.00 | 18.00 | 20.50 | 22.00 | / |

| mm | 140 | 152 | 165 | 190 | 216 | 241 | 283 | 305 | 457 | 521 | 559 | / | |

| H | in | 2.12 | 2.12 | 2.50 | 3.38 | 4.00 | 6.00 | 7.00 | 9.25 | 9.88 | 11.00 | 12.62 | / |

| mm | 55 | 55 | 65 | 85 | 100 | 150 | 180 | 235 | 250 | 280 | 320 | / | |

| W | in | 8 | 8 | 12 | 12 | 16 | 16 | 24 | 24 | 24 | 24 | 32 | / |

| mm | 200 | 200 | 300 | 300 | 400 | 400 | 600 | 600 | 600 | 600 | 800 | / | |

| WT(Kg) | RF | 3.1 | 4.1 | 6 | 9.5 | 12.8 | 20 | 26 | 45 | 126 | 216 | 270 | / |

| BW | 2.6 | 3.9 | 5.2 | 8.7 | 11.8 | 19 | 28 | 47 | 131 | 226 | 295 | / |

| Nominal pressure | PN1.6~6.4MPa |

| Nominal diameter | 15-300mm |

| The inherent flow characteristics | quick opening |

| Appliable Temperature | Hard Seal:-40~300ºC |

| Soft Seal | -40~180ºC |

| Applicable medium | Water,gas,oil quality and so on. |

| Driving Means | Manual ,Electric, Worm wheels, Pneumatic |

| Flange Type | ANSI, JIS, DIN, GB/T 9113, JB/T 79 |

| Body materials | WCB, CF8, CF8M, CF3M |

| Stem | 2Cr13, 304, 316 |

| Valve Seat | PTFE, 0Crl7Ni4Cu4Nb |

| Core Material | CF8, CF8M, CF3M. |

| Ball Type | DN200 and below sizes----Floating Ball DN200 and above sizes----Trunnion Ball |

Q1: What makes the side-entry structure beneficial?

A: It allows for easy internal maintenance without removing the valve from the line, reducing downtime and service complexity.

Q2: Is this valve suitable for automation?

A: Yes, the valve supports manual, pneumatic, and electric actuation for flexible control options.

We use high-end stainless steel and alloy steel as core materials to ensure the robustness and corrosion resistance of valves, thereby extending their service life. By integrating advanced precision casting and machining technologies, each valve undergoes strict quality inspection to ensure its sealing performance and smooth operation. We offer various specifications, pressure, and temperature ratings to meet the specific requirements of various industrial applications.