| Availability: | |

|---|---|

| Quantity: | |

Pneumatic double acting actuators are commonly used in conjunction with O-type pneumatic valves due to their simple design, compact size, light weight, and easy operation, making them very popular. They are widely used for automatic control and remote operation in various industrial sectors such as petroleum, chemical, power, and textile. O-type pneumatic valves have excellent sealing performance, ensuring smooth flow of media in pipelines and effectively preventing leaks. In addition, its high pressure and high temperature resistance enable it to maintain excellent performance even under harsh working conditions. In addition, the installation and maintenance of valves are simple, which helps to reduce production costs and improve efficiency.

● Rapid Response: In an emergency, the pneumatic emergency shut-off ball valve can be closed quickly to effectively block the fluid passage and prevent further spread of accidents. This rapid response capability is critical to ensure production safety.

● Excellent Sealing Performance: high quality sealing materials are selected to ensure that the valve can achieve complete sealing in the closed state, avoiding fluid leakage. This is of great significance for avoiding environmental pollution and ensuring stable operation of equipment.

● Easy Operation: The pneumatic device is responsible for the opening and closing of the valve, without manual intervention, reducing the complexity of operation and labor intensity. In addition, the pneumatic device is equipped with remote control function, allowing operators to control the valve from a safe distance.

| information | |

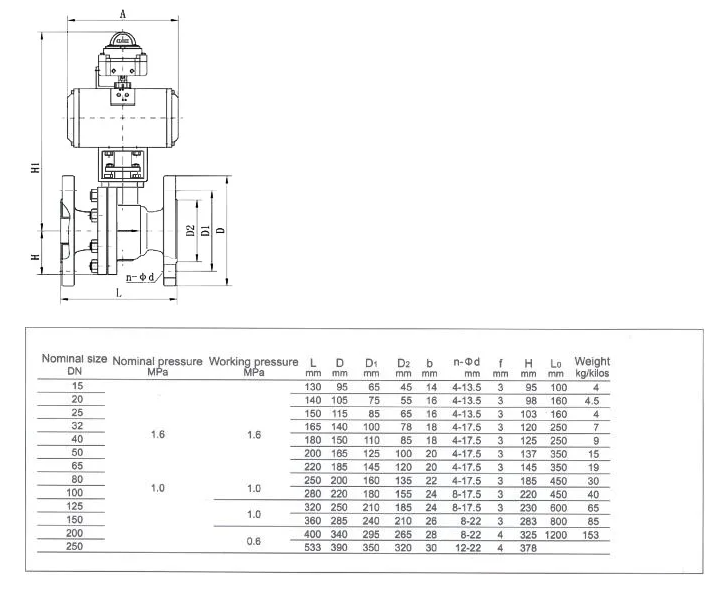

| Rated pressure (PN) | 1.6MPa, 2.5MPa, 4.0MPa, etc |

| Rated diameter (DN) | from 15mm to 1000mm; |

| Applicable media | liquids, gases, vapors, etc |

| Applicable temperature | -20 ° C to+200 ° C; |

| Sealing materials | PTFE,PE, PP, etc |

| Control mode | electric actuator control |

| Flange standards | usually GB, ANSI, DIN and other standards |

| Valve body structure | full bore, reduced diameter, V-shaped, etc |

| Material | stainless steel, carbon steel, alloy steel |

Q1:What is the main suitable of this valve?

This product is especially suitable for steel, aluminum, fiber, small solid particles, pulp, coal ash, petroleum gas and other media.

Q2:What mechanical principle is used?

Through mechanical principles, the valve is connected to the connecting shaft. Inside the cylinder, the input air pressure acts on the piston, generating thrust that drives the gear to rotate under the piston's push. The output shaft of the gear then rotates, subsequently driving the valve shaft to rotate, causing the ball valve inside to turn, changing the flow area, thus achieving regulation of the medium flow.

We have carefully crafted the pneumatic emergency stop ball valve to ensure its durability and excellent reliability. The valve design is elegant, easy to operate, capable of quickly responding to emergency situations, effectively blocking fluid media, and ensuring the safety of the production process. We are committed to providing comprehensive after-sales service to ensure that customers receive timely technical support and maintenance services during use. By choosing our pneumatic emergency shut-off ball valve, you will enjoy high-quality, high-performance, and worry free after-sales service.