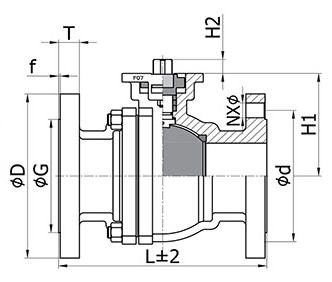

Side entry type stainless steel floating ball valve main parameterNormal Size: 1/2"~8"Pressure rating: 150 LB~900 LBMaterials: WCB, LCB, LCC, CF8...

| Availability: | |

|---|---|

| Quantity: | |

The Q341F ball valve has the same 90 degree rotation action, but the difference is that the valve body is a sphere with a circular hole or channel. Ball valves are mainly used to cut off, distribute and change the flow direction of media in pipelines. They only need 90 degree rotation and small torque to close tightly.

● Fire Safe Design: The valve with fire protection function can maintain its structural integrity and normal function in case of fire.

● Anti-Static Device: These devices effectively reduce the risk of ignition by ensuring that static electricity is safely dissipated and the operating environment is safe.

● Low Emission Control: Valves equipped with low emission control technology are designed to minimize the amount of harmful gases or vapors emitted into the atmosphere.

| Size | in | 1/2 | 3/4 | 1 | 1 1/2 | 2 | 2 1/2 | 3 | 4 | 6 | 8 | 10 | 12 |

| mm | 15 | 20 | 25 | 40 | 50 | 65 | 80 | 100 | 150 | 200 | 250 | 300 | |

| L(RF) | in | 4.25 | 4.62 | 5.00 | 6.50 | 7.00 | 7.50 | 8.00 | 9.00 | 15.50 | 18.00 | 21.00 | / |

| mm | 108 | 117 | 127 | 165 | 178 | 190 | 203 | 229 | 394 | 457 | 533 | / | |

| L1(BW) | in | 5.50 | 6.00 | 6.50 | 7.50 | 8.50 | 9.50 | 11.12 | 12.00 | 18.00 | 20.50 | 22.00 | / |

| mm | 140 | 152 | 165 | 190 | 216 | 241 | 283 | 305 | 457 | 521 | 559 | / | |

| H | in | 2.12 | 2.12 | 2.75 | 3.50 | 4.12 | 6.12 | 7.25 | 8.00 | 10.00 | 11.00 | 13.50 | / |

| mm | 55 | 55 | 70 | 90 | 105 | 155 | 185 | 205 | 255 | 280 | 345 | / | |

| W | in | 5 | 5 | 6 | 8 | 14 | 16 | 20 | 20 | 24 | 32 | 32 | / |

| mm | 130 | 130 | 160 | 200 | 350 | 400 | 500 | 500 | 600 | 800 | 800 | / | |

| WT(Kg) | RF | 2.3 | 3 | 4.5 | 7 | 9.5 | 15 | 19 | 33 | 93 | 160 | 200 | / |

| BW | 1.8 | 2.8 | 3.7 | 6.2 | 8.5 | 14 | 21 | 35 | 98 | 170 | 225 | / |

| Size | 1/2"~12" |

| Pressure rating | 150LB/300LB/600LB |

| Body material | Carbon steel,stainless steel or other material |

| Trim material | CS+ENP,13Cr,F304,F316,INCONEL,MONEL,DUPLEX.,etc |

| Driving modes | Lever,Gear,Pneumatic,Electric |

Q1: What makes the side-entry structure beneficial?

A: It allows for easy internal maintenance without removing the valve from the line, reducing downtime and service complexity.

Q2: Is this valve suitable for automation?

A: Yes, the valve supports manual, pneumatic, and electric actuation for flexible control options.

We select high-quality stainless steel and alloy steel as the primary materials to ensure the strength and corrosion resistance of the valves, thereby extending their service life. Combining modern precision casting and machining techniques, each valve undergoes rigorous quality control to ensure excellent sealing performance and smooth operation. We offer a variety of sizes, pressure ratings, and temperature classes to meet the specific needs of different industrial applications.