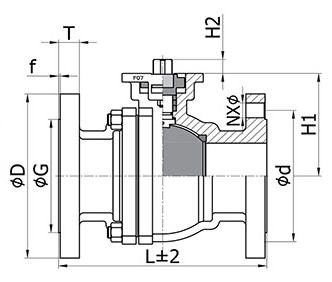

PTFE Flanged Ends 2PCS Floating Ball Valve main parameterNormal Size: 1/2"~8"Pressure rating: 150 LB~900 LBMaterials: WCB, LCB, LCC, CF8...

| Availability: | |

|---|---|

| Quantity: | |

PTFE/PFA lined ball valves are specifically designed to control common corrosive media. Its main body surface is lined with fluoroplastics such as FEP/PTFE/PTFE or other types of rubber. It has high strength and excellent corrosion resistance. It can be selected according to different working temperatures and fluid pipelines.

●Excellent Wear Resistance: Due to the use of ceramic materials, the ball and seat of the ball valve have high wear resistance, which can effectively extend the service life of the valve.

●Excellent Sealing Performance: Ceramic materials have high hardness and are not easily deformed, so they can ensure good sealing effect when the ball valve is closed, avoiding leakage.

●Strong Corrosion Resistance: Ceramic materials have excellent corrosion resistance to various chemicals, so ceramic float valves can be widely used in corrosive media such as chemistry and pharmaceuticals.

●Low Fluid Resistance: The ball of the ball valve is coaxial with the fluid channel when opened, so the resistance when the fluid passes through is small, which can effectively reduce energy consumption.

| Size | in | 1/2 | 3/4 | 1 | 1 1/2 | 2 | 2 1/2 | 3 | 4 | 6 | 8 | 10 | 12 |

| mm | 15 | 20 | 25 | 40 | 50 | 65 | 80 | 100 | 150 | 200 | 250 | 300 | |

| L(RF) | in | 4.25 | 4.62 | 5.00 | 6.50 | 7.00 | 7.50 | 8.00 | 9.00 | 15.50 | 18.00 | 21.00 | / |

| mm | 108 | 117 | 127 | 165 | 178 | 190 | 203 | 229 | 394 | 457 | 533 | / | |

| L1(BW) | in | 5.50 | 6.00 | 6.50 | 7.50 | 8.50 | 9.50 | 11.12 | 12.00 | 18.00 | 20.50 | 22.00 | / |

| mm | 140 | 152 | 165 | 190 | 216 | 241 | 283 | 305 | 457 | 521 | 559 | / | |

| H | in | 2.12 | 2.12 | 2.75 | 3.50 | 4.12 | 6.12 | 7.25 | 8.00 | 10.00 | 11.00 | 13.50 | / |

| mm | 55 | 55 | 70 | 90 | 105 | 155 | 185 | 205 | 255 | 280 | 345 | / | |

| W | in | 5 | 5 | 6 | 8 | 14 | 16 | 20 | 20 | 24 | 32 | 32 | / |

| mm | 130 | 130 | 160 | 200 | 350 | 400 | 500 | 500 | 600 | 800 | 800 | / | |

| WT(Kg) | RF | 2.3 | 3 | 4.5 | 7 | 9.5 | 15 | 19 | 33 | 93 | 160 | 200 | / |

| BW | 1.8 | 2.8 | 3.7 | 6.2 | 8.5 | 14 | 21 | 35 | 98 | 170 | 225 | / |

| Size | 1/2"~12" |

| Pressure rating | 150LB/300LB/600LB |

| Body material | Carbon steel,stainless steel or other material |

| Trim material | CS+ENP,13Cr,F304,F316,INCONEL,MONEL,DUPLEX.,etc |

| Driving modes | Lever,Gear,Pneumatic,Electric |

Q1: What makes the side-entry structure beneficial?

A: It allows for easy internal maintenance without removing the valve from the line, reducing downtime and service complexity.

Q2: Is this valve suitable for automation?

A: Yes, the valve supports manual, pneumatic, and electric actuation for flexible control options.

Our ceramic float ball valve is made of advanced ceramic materials, which have extremely high hardness and wear resistance, effectively extending the service life of the valve. Its unique design allows the ball to float freely in the fluid, achieving adaptive sealing, significantly improving sealing performance, and reducing the risk of leakage. Our ceramic float ball valve is easy to operate, has low maintenance costs, and can maintain stable performance in both high and low temperature environments. By choosing our ceramic float ball valve, you will receive high-quality, high-performance, and reliable valve solutions.