Split body reduce bore trunnion mounted ball valve have two piece and three piece body structure.middle part is bolt connection, RPTFE seal insert into stainless steel ring with spring .keep good sealling...

| Availability: | |

|---|---|

| Quantity: | |

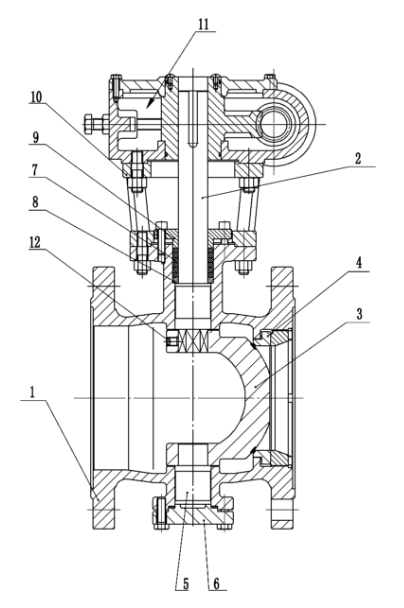

The top mounted eccentric hemispherical valve utilizes an eccentric valve body, eccentric ball, and valve seat. When the valve stem rotates, it will automatically center around a common trajectory, and the closer it closes, the better the sealing effect. The ball valve and valve seat of the valve are completely separated, eliminating the wear of the sealing ring and overcoming the problem of traditional ball valve seats and sealing surfaces always being worn. The non-metallic elastic material is embedded in the metal valve seat, and the metal surface of the valve seat is well protected. This product is particularly suitable for media such as steel, aluminum, fiber, small solid particles, pulp, coal ash, petroleum gas, etc.

● Top-Entry Structure: Internal components can be directly accessed for online maintenance, inspection, or replacement without the need to remove valves from the system.

● Gear Operation: With a simple 90 degree rotation, it achieves fast and precise control response, making it an ideal choice for on-site adjustments.

● Eccentric Hemisphere Body: Supports flexible installation of actuators or transmissions without the need for additional brackets.

| Item | Part. Name | Material |

| 1 | Bonnet | PE |

| 2 | Extension pipe | st37 |

| 3 | Body | st37 |

| 4 | Flat washer | st37 |

| 5 | Butterfly Spring | 60Si2MnA |

| 6 | Ball seat | SS202 |

| 7 | O-ring | EPDM |

| 8 | Ball washer | PTFE+20%C |

| 9 | Ball | SS304 |

| 10 | Stem washer | PTFE+20%C |

| 11 | Stem sleeve | st37 |

| 12 | Stem | SS410 |

| 13 | Stem ring | PTFE+20%C |

| 14 | Stem O-ring | FPM |

| 15 | Sleeve | st37 |

| 16 | Positioning PIN | ASTM1035 |

| 17 | Handle | st37 |

| 18 | Washer | Q235A |

| 19 | Nut | Q235A |

| 20 | Handle cap | ABS |

| Type | Nominal pressure(MPa) | Testing pressure | Suitable temperature(°C) | Suitable medium | |

| Strength (water) (MPa) | Enclose (Water) (MPa) | ||||

| Q340 H-16C | 1.6 | 2.4 | 1.76 | -40~200ºC | Water,Vapour,Oil |

| Q340 H-25C | 2.5 | 3.75 | 2.5 | ||

Q: What is the main advantage of a top-entry valve design?

A: The top-entry design allows for maintenance or part replacement without removing the valve from the pipeline—ideal for critical systems where downtime must be minimized.

Q: Is it compliant with any specific industry standards?

A: Yes, it follows API 6D/6A and ASME B16.10 design standards, including features like firesafe design, O-ring sealing, and DBB capability.

Our gear operated forged steel top inlet ball valve was manufactured with maintenance in mind. The top entrance structure and modular design make maintenance simple and minimize interruptions during inspections or repairs. This valve has DBB, self dumping seat, and fire integrity, providing reliable control and safety with each rotation. For teams seeking performance and practicality in pipeline operations, this is an ideal solution.