| Availability: | |

|---|---|

| Quantity: | |

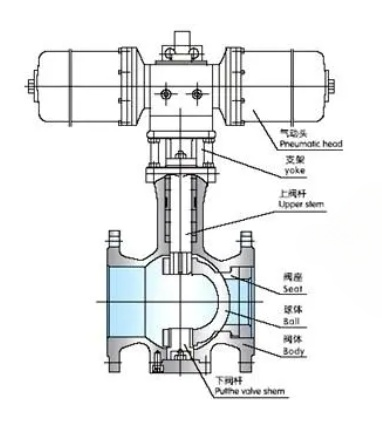

The top-mounted eccentric hemispherical valve is characterized by its eccentric body, eccentric ball, and seat. As the stem rotates, it aligns automatically with the common path, ensuring a tighter closure and superior sealing performance. The ball fully disengages from the seat, which eliminates wear issues associated with seal rings and addresses common seat and spherical surface sealing problems found in traditional ball valves. Non-metallic elastic materials are embedded in the metal seat, protecting the metal surface. This product is particularly suitable for media such as steel, aluminum, fibers, small solid particles, pulp, fly ash, and petroleum gases.

● Top-Entry Design: This configuration permits direct access to internal components for maintenance, inspection, or replacement while the system is operational, thus eliminating the need to remove valves from the system.

● Gear Operation: Rotate it just 90 degrees to achieve a fast and accurate control response, making it an ideal option for field adjustments.

● Eccentric Hemisphere: This feature facilitates flexible installation of actuators or transmissions without requiring additional brackets.

| Item | Part. Name | Material |

| 1 | Bonnet | PE |

| 2 | Extension pipe | st37 |

| 3 | Body | st37 |

| 4 | Flat washer | st37 |

| 5 | Butterfly Spring | 60Si2MnA |

| 6 | Ball seat | SS202 |

| 7 | O-ring | EPDM |

| 8 | Ball washer | PTFE+20%C |

| 9 | Ball | SS304 |

| 10 | Stem washer | PTFE+20%C |

| 11 | Stem sleeve | st37 |

| 12 | Stem | SS410 |

| 13 | Stem ring | PTFE+20%C |

| 14 | Stem O-ring | FPM |

| 15 | Sleeve | st37 |

| 16 | Positioning PIN | ASTM1035 |

| 17 | Handle | st37 |

| 18 | Washer | Q235A |

| 19 | Nut | Q235A |

| 20 | Handle cap | ABS |

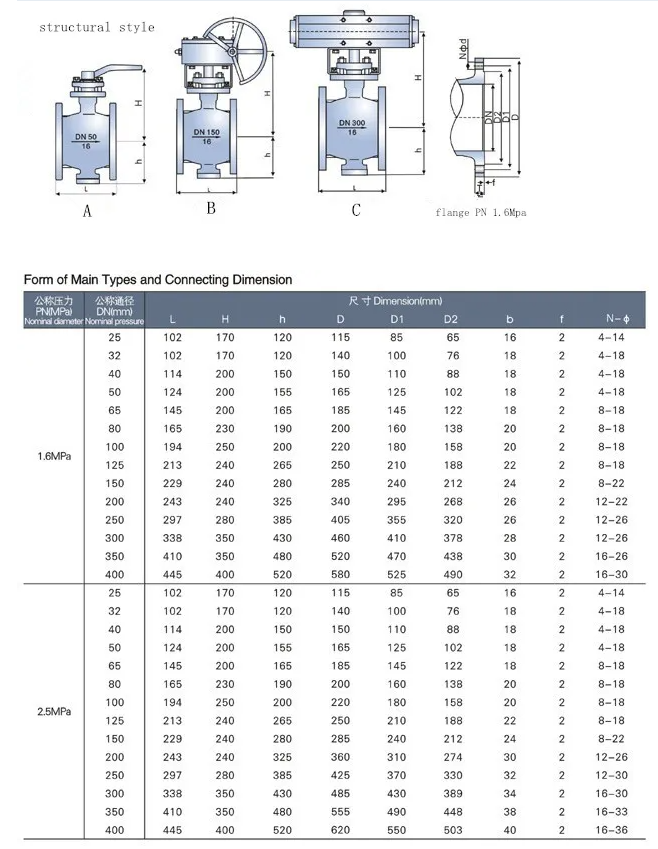

| Nominal pressure | PN1.6~6.4MPa |

| Nominal diameter | 20~400mm |

| Appliable Temperature | Hard Seal:-40~300ºC |

| Soft Seal | -40~180ºC |

| Applicable medium | Water,gas,oil quality and so on |

| Driving Means | Manual ,Electric, Worm wheels |

| Body materials | WCB, CF8, CF8M, CF3M |

| Stem | 2Cr13, 304, 316 |

| Rotary angle | 90° |

| Valve Seat | PTFE, 0Crl, 7Ni4Cu4Nb |

| Core Material | CF8, CF8M, CF3M |

Q: What is the main advantage of a top-entry valve design?

A: The top-entry design allows for maintenance or part replacement without removing the valve from the pipeline—ideal for critical systems where downtime must be minimized.

Q: Is it compliant with any specific industry standards?

A: Yes, it follows API 6D/6A and ASME B16.10 design standards, including features like firesafe design, O-ring sealing, and DBB capability.

Our gear-driven, forged steel construction, and top-mounted ball valve design fully meet maintenance requirements. The top-mounted structure and modular design facilitate maintenance, reducing downtime during inspections or repairs. The valve features double block and bleed (DBB), self-tilting seats, and fire integrity, ensuring reliable control and safe operation with each rotation. It is an ideal choice for teams that prioritize pipeline performance and practicality.