Side entry type stainless steel floating ball valve main parameterNormal Size: 1/2"~8"Pressure rating: 150 LB~900 LBMaterials: WCB, LCB, LCC, CF8...

| Availability: | |

|---|---|

| Quantity: | |

Flanged Ends Tank Bottom Discharge Ball Valve is mainly used at the bottom of the storage tank, reaction kettle and other containers. It eliminate the process medium residual phenomenon, according to the actual situation. It can be divided into plain end or oblique end. The working principle of PTFE Lined baiting ball valve is by rotating the ball to keep the valve open or close. Its features as switch light, small volume, reliable sealing, simple structure, easy maintenance, widely used.

The valve body, disc(ball) and other wetted parts in contact with the medium is lined by fluorine plastic FEP, PTFE and PFA. It can sustain any corrosive medium in addition to the molten alkali metals and flurine elements. Its is ideal products used in chlor-alkali, industrial in organic chemicals, metal and mining, nitrogen and phosphatic, fertilizers, petroleum refining, pharmaceutical etc.

● Strong Material: strong corrosion resistance, can maintain long-term stability in complex working conditions.

● Design Is Ingenious: ball valve is easy to operate, quick opening and closing, which helps improve the efficiency of operation.

● Excellent Sealing Effect: stainless steel discharge ball valve can effectively prevent the leakage of media, to ensure production safety.

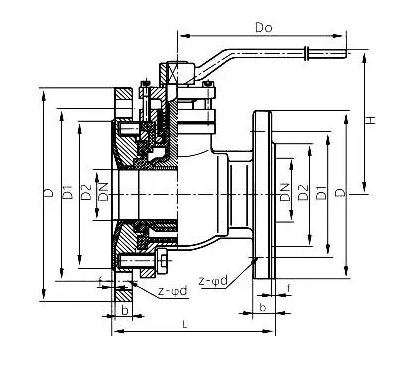

| DN | D | D1 | D2 | D3 | D4 |

| 25/32 | 115 | 85 | 65 | 140 | 100 |

| 32/40 | 140 | 100 | 78 | 150 | 110 |

| 40/50 | 150 | 110 | 85 | 165 | 125 |

| 50/65 | 165 | 125 | 100 | 185 | 145 |

| 65/80 | 185 | 145 | 120 | 200 | 160 |

| 80/100 | 200 | 160 | 135 | 220 | 180 |

| 100/125 | 220 | 180 | 155 | 250 | 210 |

| 125/150 | 250 | 210 | 185 | 285 | 240 |

| 150/200 | 285 | 240 | 210 | 340 | 295 |

| 200/250 | 340 | 295 | 265 | 405 | 355 |

| Design & Manufacture Standard | HG/T 3704, GB/T 12237, API6D | |||

| Fact to Face Dimension Standard | HG/T 3704, GB/T 12221 | |||

| Flange Standard | HG/T20592, GB/T 9119, ASME B16.5 | |||

| Inspection and Test Standard | GB/T 13927, JB/T 9092, API598 | |||

| Mark Standard | GB/T12241, GB/T12220, MSS 25 | |||

| Delivery Standard | JB/T7928 | |||

| Nominal Diameter | DN25-DN200 | |||

| Nominal Pressure | PN10 | PN16 | 150LB | |

| Test Pressure ( MPA) | Shell Test | 1.5 | 1.5 | 1.5 |

| High Pressure Sealing | 1.1 | 1.1 | 1.1 | |

| Low Pressure Sealing | 0.6 | 0.6 | 0.6 | |

| Applicable Temperature Range ( ºC) | PFA: -29 ~ 200, PTFE: -29~ 180, FEP: -29~ 150, GXPO: -10~80 | |||

| Applicable Medium | Strong Corrosive Medium i.e, Nitric acid, Liquid Chlorine, Sulfuric Acid and Aqua regia etc. | |||

Q1: What makes the side-entry structure beneficial?

A: It allows for easy internal maintenance without removing the valve from the line, reducing downtime and service complexity.

Q2: Is this valve suitable for automation?

A: Yes, the valve supports manual, pneumatic, and electric actuation for flexible control options.

Our stainless steel ball valves are manufactured from high-quality stainless steel materials, ensuring the valve's corrosion resistance and durability. Whether in harsh industrial environments or during chemical processes requiring high purity, they perform excellently. Our ball valve design is unique and easy to operate. The ball structure allows for quick and smooth opening and closing, reducing operational difficulty and time. At the same time, the sealing performance is superior, effectively preventing medium leakage and ensuring production safety. We pay attention to details and offer personalized customization services. Whether it's the valve size, connection method, or operating mode, we can customize according to your specific needs, ensuring that the valve perfectly matches your process system.