One Piece Body self-filtering fully welded Ball ValveTechnology BackgroundIn the transmission pipeline of fluid media, the ball valve is an effective and necessary cutoff device. In order to remove the impurities and dirt from the fluid media and keep the transmission pipeline clean and unblocked, a filter set in...

| Availability: | |

|---|---|

| Quantity: | |

The fully welded ball valve is renowned for its ingenious structural design, which employs advanced welding techniques to ensure a tight fit between the valve body, seat, and ball. This design significantly enhances the valve's strength and sealing performance, allowing it to operate stably even under extreme conditions such as high pressure and high temperature. Thanks to its outstanding performance, the fully welded ball valve is widely used in industries like oil, chemical, and natural gas, becoming an essential component in these sectors.

● Compact Structure: The fully welded integral ball valve features an integrated design that reduces the number of connection components, making the structure more compact and space-saving. This design not only simplifies installation and maintenance but also enhances sealing performance.

● Excellent Sealing Performance: Welded connections eliminate common leakage issues found in traditional methods, ensuring the stable flow of the medium inside the pipeline.

● Strong Corrosion Resistance: The ball valve body is typically made from corrosion-resistant materials like stainless steel, effectively resisting the erosion of various corrosive media and extending its service life.

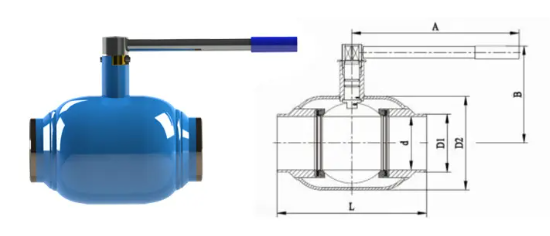

| Size | A | B | L | D | D1 | D2 | |

| in | mm | mm | mm | mm | mm | mm | mm |

| 1/2 | 15 | 129 | 64 | 210 | 15 | 21.3 | 42 |

| 3/4 | 20 | 129 | 64 | 230 | 15 | 26.7 | 42 |

| 1 | 25 | 159 | 76 | 230 | 20 | 33.4 | 48 |

| 1 1/4 | 32 | 159 | 85 | 260 | 25 | 42.2 | 60 |

| 1 1/2 | 40 | 230 | 95 | 300 | 32 | 48.3 | 76 |

| 2 | 50 | 230 | 100 | 300 | 40 | 60.3 | 89 |

| 2 1/2 | 65 | 300 | 159 | 300 | 50 | 76.1 | 114 |

| 3 | 80 | 300 | 170 | 300 | 65 | 88.9 | 140 |

| 4 | 100 | 450 | 192 | 325 | 80 | 114.3 | 185 |

| 5 | 125 | 450 | 208 | 325 | 100 | 141.3 | 216 |

| 6 | 150 | 450 | 241 | 350 | 125 | 168.3 | 219 |

| Pressure class | Class150-2,500, PN 10-420 |

| Diameter range | DN 15~ 1400 (1/2"~56") |

| Temperature | -50ºC~280ºC |

| Connecting type | flange |

| Ball | floating ball or trunnion mounted |

| Applicable medium | water,gas,oil, etc |

| Driving means | manual, gearboxes, electric, pneumatic, hydraulic, etc |

| Available Material | SS,CS, A105,A216,CF8,CF8M, LCB, LCC, etc. ( Selected at clients'request ) |

Q1:What is the main suitable of this valve?

This product is especially suitable for steel, aluminum, fiber, small solid particles, pulp, coal ash, petroleum gas and other media.

Q2:What mechanical principle is used?

The mechanical principle of the fully welded ball valve lies in its sophisticated design, which ensures reliable fluid control. The valve features a spherical disc, or ball, with a bore that can be rotated 90 degrees between open and closed positions. When the bore is aligned with the pipeline, fluid flows freely through the valve.

Our fully welded ball valves boast several significant advantages. Firstly, their robust design ensures long-lasting durability and reliability, capable of withstanding a variety of extreme industrial environments. Secondly, by employing advanced seamless welding technology, we have effectively eliminated potential leakage risks, significantly enhancing the product's safety and overall performance. Lastly, our commitment to quality and innovation ensures that the valves fully comply with the latest industry standards, maximizing your return on investment.