| Availability: | |

|---|---|

| Quantity: | |

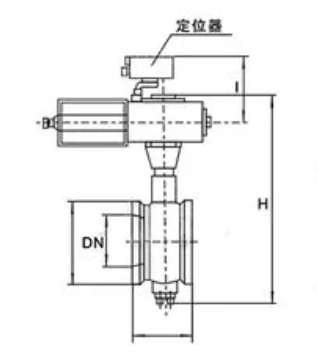

The pneumatic V-type regulating ball valve combines hard sealing and PTFE sealing technology, with regulating function. The valve is designed with a replaceable seat equipped with a spring to ensure no obstruction or detachment between the seat and the sphere, thus achieving stable sealing effect and lasting service life. The core component of the V-type ball valve, —— V-type groove, has specially designed an optimized switching mechanism to make the flow large and the pressure small, while ensuring accurate interception and control performance. Its flow characteristics remain almost consistent. In addition, the opening-closing mechanism of the valve adopts the V-type spherical structure, which effectively avoids the accumulation of media in the valve room.

●V-shaped notch design: The shear force between the ball and the metal seat V-shaped notch is particularly suitable for media containing fibers, small solid particles, pulp, etc.

● Low pressure loss: Fully open the flow rate to minimize pressure loss and prevent the medium from depositing in the body cavity.

●Long service life: The valve seat structure adopts a spring-loaded movable valve seat structure, which prevents problems with the ball core and valve seat, ensures reliable sealing, and has a long service life.

● Precise adjustment: This valve has the advantages of precise adjustment, reliable positioning function, similar flow characteristics, large adjustment range, and a maximum adjustment ratio of 100:1.

| DN(mm) | 25 | 32 | 40 | 50 | 65 | 80 | 100 | 150 | 200 | 250 | 300 | 350 | 400 |

| Kv | 22 | 36 | 58 | 82 | 145 | 200 | 355 | 798 | 418 | 2209 | 3185 | 4309 | 5664 |

| P(MpA) | 14 | 8 | 10 | 9 | 20 | 14 | 8 | 6 | 3.5 | 1.6 | 2.5 | 2 | 1.5 |

| Nominal pressure | PN1.6~6.4MPa |

| Nominal diameter | 20~400mm |

| Appliable Temperature | Hard Seal:-40~300ºC Soft Seal: -40~180ºC |

| Applicable medium | Water,gas,oil quality and so on |

| Driving Means | Manual ,Electric, Worm wheels, Pneumatic |

| Body materials | WCB, CF8, CF8M, CF3M |

| Stem | 2Cr13, 304, 316 |

| Rotary angle | 90° |

| Valve Seat | PTFE, 0Crl, 7Ni4Cu4Nb |

| Core Material | CF8, CF8M, CF3M |

Q:What is the purpose of the V Incision design?

The unique design of the v-type port not only optimizes the fluid flow but also reduces the pressure loss, thereby increasing the efficiency of the whole system.

Q:What types of media can this valve handle?

This type of valve is very suitable for high-viscosity media, such as heavy oil, glue, and other substances that are easily cured at room temperature.

Our pneumatic v-ball valves are tested in many industrial applications due to their excellent performance and stability. It provides stable and reliable performance for fine operations requiring precise flow control, even in high temperatures, high pressure, and harsh environments. Valve design emphasizes the user experience and simplifies the installation, maintenance and operation process, making it more convenient and efficient. The unique design of the v-type port not only optimizes the fluid flow but also reduces the pressure loss, thereby increasing the efficiency of the whole system. In addition, we also provide comprehensive after-sales service and technical support to ensure that customers get timely help to solve any problems encountered in the use process.