| Availability: | |

|---|---|

| Quantity: | |

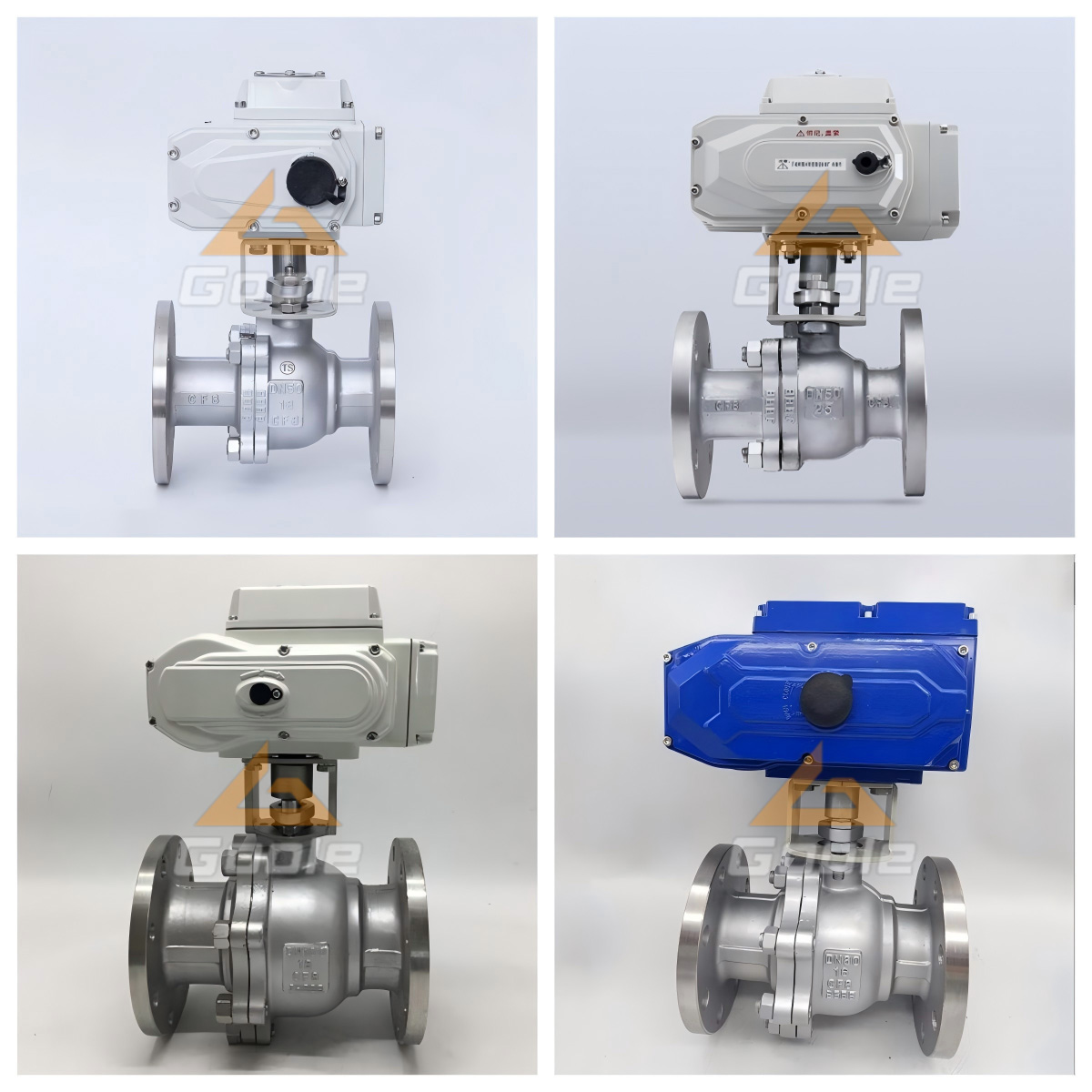

Fixed electric ball valve is suitable for two position cut-off and adjustment situations. The connection between the valve and the actuator adopts a direct connection method. The electric actuator is equipped with a servo system, without the need for an additional servo amplifier. The operation can be controlled by inputting a 4-20mA signal and a 220VAC power supply. It has the advantages of simple connection, compact structure, small size, light weight, low resistance, and stable and reliable operation. The actuator can be equipped with electronic electric actuators such as UNIC, PSQ, HQ, DHL, or gas piston actuators such as GTX and AL according to user requirements.

● Anti-Static Structure: Trunnion ball top entry ball is provided with the anti-static structure and adopts the static electricity discharge device to directly form a static channel between the ball and body or between the ball and body through the stem.

● Trunnion-Mounted Ball: Features a fixed ball and floating seat rings ,Bearing absorb the side load generated by the pressure acting on the ball.

● Self-Seated Valves:In valves designed for standard service, a resilient material is inserted into the metal seat holder to provide a soft-seating acting in addition to the metal -to -metal seating between the ball and seat rings.

| SIZE | 1/2" | 3/4" | 1" | 1 1 / 4 " | 1 1 / 2 " | 2" | 2 1 / 2 " | 3" | 4" | 5" | 6" | 8" |

| d | 15 | 19 | 23.5 | 30 | 36 | 45 | 58 | 67 | 76 | 100 | 125 | 195 |

| L | 35 | 38 | 40 | 50 | 60 | 72 | 95 | 118 | 140 | 195 | 260 | 350 |

| D | 95 | 105 | 115 | 135 | 145 | 160 | 180 | 195 | 215 | 245 | 280 | 335 |

| D1 | 65 | 75 | 85 | 100 | 110 | 125 | 145 | 160 | 180 | 210 | 240 | 295 |

| D2 | 45 | 55 | 65 | 78 | 85 | 100 | 120 | 135 | 155 | 185 | 210 | 265 |

| H | 62 | 70 | 79 | 86 | 92 | 102 | 158 | 172 | 187 | 200 | 240 | 278 |

| E | 110 | 125 | 135 | 150 | 150 | 180 | 250 | 300 | 350 | 650 | 840 | 1000 |

| b | 14 | 14 | 16 | 16 | 18 | 20 | 22 | 24 | 24 | 26 | 26 | 28 |

| z-d1 | 4-14 | 4-14 | 4-14 | 4-18 | 4-18 | 4-18 | 4-18 | 8-18 | 8-18 | 8-18 | 8-23 | 12-20 |

| f | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 | 3 |

| information | |

| Rated pressure (PN) | 1.6MPa, 2.5MPa, 4.0MPa, etc |

| Rated diameter (DN) | from 15mm to 1000mm; |

| Applicable media | liquids, gases, vapors, etc |

| Applicable temperature | -20 ° C to+200 ° C; |

| Sealing materials | PTFE,PE, PP, etc |

| Control mode | electric actuator control |

| Flange standards | usually GB, ANSI, DIN and other standards |

| Valve body structure | full bore, reduced diameter, V-shaped, etc |

| Material | stainless steel, carbon steel, alloy steel |

Q1:What is the main suitable of this valve?

This product is particularly suitable for media such as steel, aluminum, fiber, small solid particles, pulp, coal ash, petroleum gas, etc.

Q2:What mechanical principle is used?

Using the principle of Mechanism and the valve connected with the connecting shaft. The input electric pressure inside the electric actuator, acting on the piston to produce certain thrust, so that the gear output in piston driven, so that the gear output shaft to rotate, and drives the valve shaft to rotate, so that the ball valve in the valve with the valve to rotate, changing the circulation area, to change the media flow valve purpose.

We use advanced materials and technology to manufacture electric emergency shut-off valves, ensuring their durability and reliability. In emergencies, these valves can respond quickly to cut off the flow of fluid, protecting people and property. Combined with advanced control systems, our electric emergency shut-off valves enable remote monitoring and operation, enhancing safety and convenience. Suitable for various industrial environments, such as oil, chemical, and natural gas sectors, they meet diverse needs.