| Availability: | |

|---|---|

| Quantity: | |

The Carbon Steel Flange Floating Ball Valve is designed to provide efficient fluid control across various piping systems. Constructed with a floating ball mechanism, this valve ensures smooth operation and quick flow direction changes with a 90-degree rotation. The flanged connection makes installation straightforward and secure, while the durable carbon steel construction offers strength and reliability, even in demanding industrial environments. Ideal for applications involving water, gas, and oil, this valve provides a versatile solution for industries requiring flexible flow management.

● Floating Ball Design: Ensures smooth operation and efficient fluid control by allowing the ball to move with the flow of the medium.

● Flanged Connections: Easy to install and maintain, providing secure, leak-proof connections in piping systems.

● Quick Operation: The valve requires just a 90-degree rotation to open or close, providing fast and simple flow control.

| No | Part Name | ASTM Material | ||

| Carbon steel | 18Cr-9Ni-2Mo | Low temp steel | ||

| 1 | Body | A105 | A182-F316 | A350-LF2 |

| 2 | Bonnet | A105 | A182-F316 | A350-LF2 |

| 3 | Ball | A182-F304 | A182-F316 | A182-F304 |

| 4 | Stem | A276-304 | A276-316 | A276-304 |

| 5 | Seat ring | R.PTFE | ||

| 6 | Gasket | Graphite+304 | PTFE | Graphite+304 |

| 7 | Stud | A193-B7 | A193-B8 | A320-L7 |

| 8 | Nut | A194-2H | A194-8 | A194-4 |

| 9 | Packing | PTFE | ||

| 10 | Gland | A105 | A182-F316 | A350-LF2 |

| 11 | Gland bolt | A193-B7 | A193-B8 | A193-B7 |

| 12 | Stop plate | Carbon steel | Carbon steel+Zn | Carbon steel |

| 13 | Handle | Carbon steel | ||

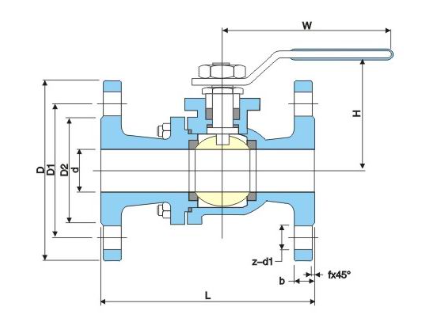

| Size | in | 1/2 | 3/4 | 1 | 1 1/2 | 2 | 2 1/2 | 3 | 4 | 6 | 8 | 10 | 12 |

| mm | 15 | 20 | 25 | 40 | 50 | 65 | 80 | 100 | 150 | 200 | 250 | 300 | |

| L(RF) | in | 4.25 | 4.62 | 5.00 | 6.50 | 7.00 | 7.50 | 8.00 | 9.00 | 15.50 | 18.00 | 21.00 | / |

| mm | 108 | 117 | 127 | 165 | 178 | 190 | 203 | 229 | 394 | 457 | 533 | / | |

| L1(BW) | in | 5.50 | 6.00 | 6.50 | 7.50 | 8.50 | 9.50 | 11.12 | 12.00 | 18.00 | 20.50 | 22.00 | / |

| mm | 140 | 152 | 165 | 190 | 216 | 241 | 283 | 305 | 457 | 521 | 559 | / | |

| H | in | 2.12 | 2.12 | 2.50 | 3.38 | 4.00 | 6.00 | 7.00 | 9.25 | 9.88 | 11.00 | 12.62 | / |

| mm | 55 | 55 | 65 | 85 | 100 | 150 | 180 | 235 | 250 | 280 | 320 | / | |

| W | in | 8 | 8 | 12 | 12 | 16 | 16 | 24 | 24 | 24 | 24 | 32 | / |

| mm | 200 | 200 | 300 | 300 | 400 | 400 | 600 | 600 | 600 | 600 | 800 | / | |

| WT(Kg) | RF | 3.1 | 4.1 | 6 | 9.5 | 12.8 | 20 | 26 | 45 | 126 | 216 | 270 | / |

| BW | 2.6 | 3.9 | 5.2 | 8.7 | 11.8 | 19 | 28 | 47 | 131 | 226 | 295 | / |

| Nominal pressure | PN1.6~6.4MPa |

| Nominal diameter | 15-300mm |

| The inherent flow characteristics | quick opening |

| Appliable Temperature | Hard Seal:-40~300ºC |

| Soft Seal | -40~180ºC |

| Applicable medium | Water,gas,oil quality and so on. |

| Driving Means | Manual ,Electric, Worm wheels, Pneumatic |

| Flange Type | ANSI, JIS, DIN, GB/T 9113, JB/T 79 |

| Body materials | WCB, CF8, CF8M, CF3M |

| Stem | 2Cr13, 304, 316 |

| Valve Seat | PTFE, 0Crl7Ni4Cu4Nb |

| Core Material | CF8, CF8M, CF3M. |

| Ball Type | DN200 and below sizes----Floating Ball DN200 and above sizes----Trunnion Ball |

Q1:What is the benefit of the floating ball design?

The floating ball design allows for smooth, efficient flow control as the ball moves with the flow of the fluid, ensuring minimal resistance and optimal performance.

Q2:What is the valve's temperature and pressure range?

The valve can handle temperatures from -40ºC to 300ºC (hard seal) or -40ºC to 180ºC (soft seal) and is rated for nominal pressures from PN1.6 to 6.4 MPa.

Applications is designed for ease of installation and long-term performance. Constructed from corrosion-resistant carbon steel, this valve ensures reliable operation in demanding conditions. The floating ball design provides smooth and efficient flow control, while the flanged connection guarantees a secure fit. Whether you need to control water, gas, or oil in industrial piping systems, our valve offers a versatile, high-performance solution that meets the needs of diverse applications.