| Availability: | |

|---|---|

| Quantity: | |

Orbital ball valves controls fluid flow by rotating a ball, primarily used for cutting off, distributing, and changing the direction of the medium. It operates by rotating the ball to open or close the valve. The design features of the orbital ball valve include frictionless operation, low-torque design, and self-cleaning sealing surfaces, which make it excel in various industrial applications.

● Excellent Sealing Performance: Advanced sealing technology and materials are used to ensure good sealing effect in high pressure and high temperature environment, effectively preventing leakage.

● Strong Circulation Capacity: Small flow resistance can reduce the pressure loss of the pipeline system and improve the efficiency of fluid transportation.

● Easy to Operate: Quick start and stop, only need to rotate 90 degrees to complete the switching action, easy to automatic control and remote operation.

NO. | Part name | Material | ||||||

A216 WCB | A217 WC9 | A217 C5 | A351 CF8 | A351 CF8M | A351 CF3 | A351 CF3M | ||

1 | Body | A216 WCB | A217 WCB | A217 C5 | A351 CF8 | A351 CF8M | A351 CF3 | A351 CF3M |

2 | Plug | A351 CF8 | A351 CF8 | A351 CF8 | A351 CF8 | A351 CF8M | A351 CF3 | A351 CF3M |

3 | Gasket | Flexible graphite+stainless steel/PTFE | ||||||

4 | Cover | A216 WCB | A217 WC9 | A217 C5 | A351 CF8 | A351 CF8M | A351 CF3 | A351 CF3M |

5 | Bolt | A193 B7 | A193 B16 | A193 B16 | A1293 B8 | A193 B8M | ||

6 | Nut | A194 2H | A194 4 | A194 4 | A194 8 | A194 8M | ||

7 | Packing | Flexible graphite/PTFE | ||||||

8 | Gland | A216 WCB | A216 WC9 | A216 C5 | A351 CF8 | A351 CF8M | ||

9 | Wrench | A216 WCB | A216 WC9 | A216 C5 | A351 CF8 | A351 CF8M | ||

10 | Yoke nut | A439-D2/Cu-Allog | ||||||

11 | Hand wheel | ASTM A536 Gr.60-40-18 A216 WCB | ||||||

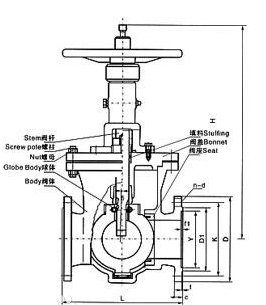

Main Dimensions

| Size | inch | 1/2 | 3/4 | 1 | 1-1/4 | 1-1/2 | 2 | 2-1/2 | 3 | 4 | 5 | 6 | 8 | 10 | 12 | 14 |

L-RF | mm | 108 | 117 | 127 | 140 | 165 | 178 | 190 | 203 | 229 | 254 | 267 | 292 | 330 | 356 | 381 |

H | mm | 190 | 195 | 225 | 260 | 280 | 310 | 340 | 395 | 435 | 470 | 535 | 590 | 630 | 680 | 720 |

W | mm | 120 | 140 | 140 | 180 | 200 | 220 | 260 | 300 | 300 | 340 | 400 | 450 | 450 | 500 | 500 |

Weight | Kg | 9 | 10 | 11 | 17 | 19 | 23 | 25 | 32 | 55 | 82 | 98 | 130 | 178 | 250 | 380 |

| TYPE | ORBIT BALL VALVE | SIZE | 1/2"--48"(DN15--DN1200) |

| STRUCTURE | TRUNNION BALL VALVE | PRESSURE RATING | ANSI CLASS 150--2500(1.6MPa--42.0MPa) |

| CONNECTION | THREADED, WELDED,FLANGE END | FUCTION | BLOW-DOWN VALVE |

| OPERATION | MANUAL,PNEUMATIC,ELECTRIC | APPLICATION | INDUSTRIAL USAGE |

| PRODUCTION CAPACITY | 1000000PCSNEAR | PACKAGE | PLYWOOD CASE |

| WARRANTY PERIOD | 12 MONTHS | TRADE MARK | GOOLE,OEM |

| ORIGIN | WENZHOU ZHEJIANG | HS CODE | 84819090 |

Q:What is the advantage of the top-entry design?

The design allows for in-line servicing, meaning internal parts can be accessed and replaced without having to remove the valve from the pipeline, significantly reducing maintenance time.

Q:Is this valve suitable for high-demand or critical applications?

Yes, the valve features firesafe design, double block and bleed (DBB) functionality, and self-relieving seats, making it ideal for critical and high-demand applications.

Q:How does the gear-operated mechanism benefit this valve?

The gear-operated mechanism enables precise and easy control of fluid flow, making it suitable for high-pressure systems where consistent operation is essential.

Our orbital ball valves are manufactured from high-quality stainless steel and special alloy materials, ensuring stable operation in high-pressure, high-temperature, and corrosive environments, thus extending their service life. Advanced manufacturing techniques and precision testing equipment ensure that each valve achieves optimal sealing performance and fluidity, reducing leakage risks and enhancing system efficiency. We offer a variety of ball valve specifications and configurations to meet the needs of different application scenarios, whether on industrial production lines or in complex fluid control systems, we can find the most suitable solution.