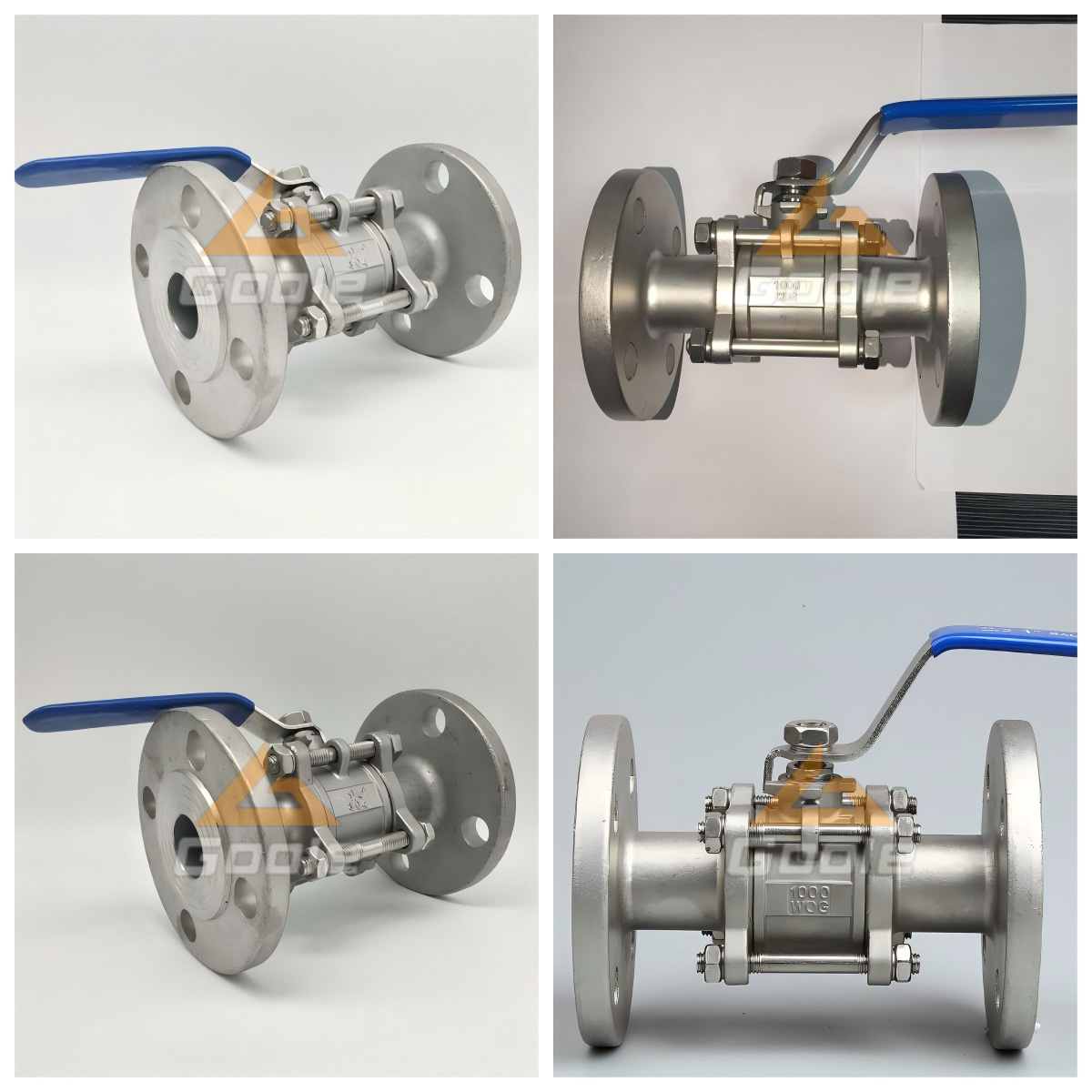

The three-way flanged ball valve and the gate valve are both types of valves, but they differ in that the ball valve uses a ball that rotates on its central axis to open and close. The ball valve is primarily utilized in pipelines to shut off, distribute, and redirect the flow of media.

● Reasonable Design: A compact structure that effectively reduces installation space, allowing the valve to be flexibly utilized in various pipeline systems.

● Corrosion Resistance: Manufactured from high-quality materials, the valve offers excellent wear resistance and a long service life.

● Flange Connection: This connection method ensures a tight bond between the valve and the pipeline, reducing the likelihood of leaks and enhancing the system's sealing and safety.

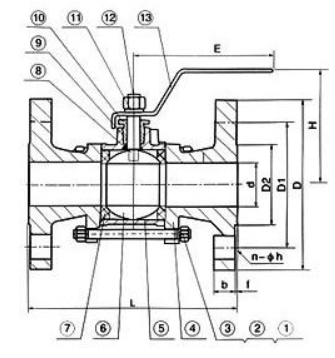

| Serial number | Part Name | Material | |

| - | - | Stainless steel | carbon steel |

| 1 | bolt | Stainless steel SS304 | carbon steel |

| 2 | spring washer | Stainless steel SS304 | Stainless steel SS304 |

| 3 | nut | Stainless steel SS304 | carbon steel |

| 4 | cap | Stainless steel CF8/CF8M | Carbon SteelWCB |

| 5 | valve body | Stainless steel CF8/CF8M | Carbon SteelWCB |

| 6 | sphere | Stainless steel CF8 | Stainless steel CF8 |

| 7 | sealing ring | Polytetrafluoroethylene/PTFE | PolytetrafluoroethylenePTFE |

| 8 | Stem | Stainless steel SS316 | Stainless steel SS304 |

| 9 | filler | PolytetrafluoroethylenePTFE | PolytetrafluoroethylenePTFE |

| 10 | Compression nut | Stainless steel SS304 | Stainless steel SS304 |

| 11 | spring washer | Stainless steel SS304 | Stainless steel SS304 |

| 12 | nut | Stainless steel SS304 | Stainless steel SS304 |

| 13 | handle | Stainless steel SS304 | Stainless steel SS304 |

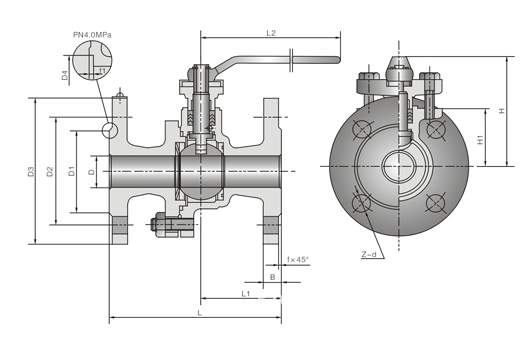

| SIZE | 1/2″ | 3/4″ | 1" | 1 1/4″ | 1 1/2″ | 2" | 2 1/2″ | 3″ | 4″ |

| d | 15 | 20 | 25 | 32 | 38 | 50 | 65 | 76 | 100 |

| L | 130 | 150 | 160 | 180 | 200 | 230 | 290 | 310 | 350 |

| D | 95 | 105 | 115 | 135 | 145 | 160 | 180 | 195 | 230 |

| D1 | 65 | 75 | 85 | 100 | 110 | 125 | 145 | 160 | 190 |

| D2 | 45 | 55 | 65 | 78 | 85 | 100 | 120 | 135 | 160 |

| b | 14 | 16 | 16 | 18 | 18 | 20 | 22 | 24 | 24 |

| f | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 3 | 3 |

| H | 75 | 95 | 90 | 110 | 130 | 140 | 140 | 180 | 250 |

| W | 130 | 140 | 140 | 170 | 200 | 220 | 220 | 350 | 550 |

| n-do | 4-14 | 4-14 | 4-14 | 4-18 | 4-18 | 8-18 | 8-18 | 8-18 | 8-22 |

| Nominal Size | 1/2"-4" |

| Nominal pressure | 1.6Mpa-25Mpa |

| Temperature | -20ºC~220ºC |

| Medium | water, oil, gas and some corrosive mediun |

| Connection type | Flange, butt welded, threaded |

| Operation | manual, electric, pneumatic |

Q1:What is the benefit of the floating ball design?

The floating ball design allows for smooth, efficient flow control as the ball moves with the flow of the fluid, ensuring minimal resistance and optimal performance.

Q2:What is the valve's temperature and pressure range?

The valve can handle temperatures from -40ºC to 300ºC (hard seal) or -40ºC to 180ºC (soft seal) and is rated for nominal pressures from PN1.6 to 6.4 MPa.

Our three-piece flanged welded ball valve is crafted from high-quality materials, ensuring durability and reliability. Its unique design facilitates easy installation and maintenance, significantly enhancing work efficiency. The ball valve features excellent sealing performance, effectively preventing leaks and ensuring safe and stable system operation. Lastly, we provide comprehensive after-sales service to ensure customers receive timely technical support and solutions during use.