Three piece flange ball valve and gate valve belong to the same type of valve, with the difference being that their closing part is a sphere, which rotates around the centerline of the valve body to achieve opening and closing. Ball valves are mainly used in pipelines to cut off, distribute, and change the flow direction of the medium.

● Reasonable Design: Compact structure, effectively reducing the installation space, so that the valve can be flexibly applied in various pipeline systems.

● Corrosion Resistance: Made of high quality materials, ensuring that the valve has good wear resistance, prolonging the service life.

● Flanged Connection: The connection mode makes the valve and pipeline connected firmly, not easy to leak, improve the sealing and safety of the system.

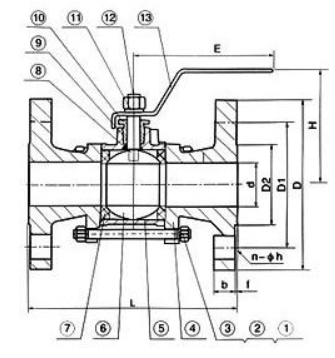

| Serial number | Part Name | Material | |

| - | - | Stainless steel | carbon steel |

| 1 | bolt | Stainless steel SS304 | carbon steel |

| 2 | spring washer | Stainless steel SS304 | Stainless steel SS304 |

| 3 | nut | Stainless steel SS304 | carbon steel |

| 4 | cap | Stainless steel CF8/CF8M | Carbon SteelWCB |

| 5 | valve body | Stainless steel CF8/CF8M | Carbon SteelWCB |

| 6 | sphere | Stainless steel CF8 | Stainless steel CF8 |

| 7 | sealing ring | Polytetrafluoroethylene/PTFE | PolytetrafluoroethylenePTFE |

| 8 | Stem | Stainless steel SS316 | Stainless steel SS304 |

| 9 | filler | PolytetrafluoroethylenePTFE | PolytetrafluoroethylenePTFE |

| 10 | Compression nut | Stainless steel SS304 | Stainless steel SS304 |

| 11 | spring washer | Stainless steel SS304 | Stainless steel SS304 |

| 12 | nut | Stainless steel SS304 | Stainless steel SS304 |

| 13 | handle | Stainless steel SS304 | Stainless steel SS304 |

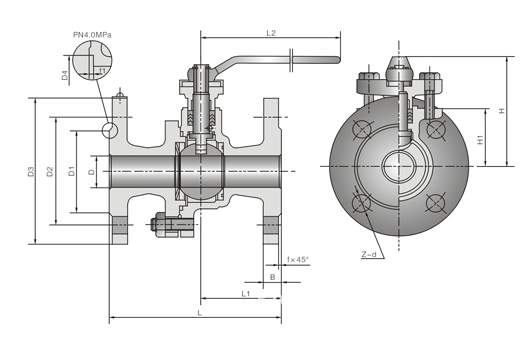

| SIZE | 1/2″ | 3/4″ | 1" | 1 1/4″ | 1 1/2″ | 2" | 2 1/2″ | 3″ | 4″ |

| d | 15 | 20 | 25 | 32 | 38 | 50 | 65 | 76 | 100 |

| L | 130 | 150 | 160 | 180 | 200 | 230 | 290 | 310 | 350 |

| D | 95 | 105 | 115 | 135 | 145 | 160 | 180 | 195 | 230 |

| D1 | 65 | 75 | 85 | 100 | 110 | 125 | 145 | 160 | 190 |

| D2 | 45 | 55 | 65 | 78 | 85 | 100 | 120 | 135 | 160 |

| b | 14 | 16 | 16 | 18 | 18 | 20 | 22 | 24 | 24 |

| f | 2 | 2 | 2 | 3 | 3 | 3 | 3 | 3 | 3 |

| H | 75 | 95 | 90 | 110 | 130 | 140 | 140 | 180 | 250 |

| W | 130 | 140 | 140 | 170 | 200 | 220 | 220 | 350 | 550 |

| n-do | 4-14 | 4-14 | 4-14 | 4-18 | 4-18 | 8-18 | 8-18 | 8-18 | 8-22 |

| Nominal Size | 1/2"-4" |

| Nominal pressure | 1.6Mpa-25Mpa |

| Temperature | -20ºC~220ºC |

| Medium | water, oil, gas and some corrosive mediun |

| Connection type | Flange, butt welded, threaded |

| Operation | manual, electric, pneumatic |

Q1:What is the benefit of the floating ball design?

The floating ball design allows for smooth, efficient flow control as the ball moves with the flow of the fluid, ensuring minimal resistance and optimal performance.

Q2:What is the valve's temperature and pressure range?

The valve can handle temperatures from -40ºC to 300ºC (hard seal) or -40ºC to 180ºC (soft seal) and is rated for nominal pressures from PN1.6 to 6.4 MPa.

Our three-piece flanged welded ball valve is made from high-quality materials, ensuring the product's durability and reliability. Its unique design makes installation and maintenance exceptionally easy, significantly improving work efficiency. The ball valve boasts excellent sealing performance, effectively preventing leaks and ensuring the safe and stable operation of the system. Finally, we offer comprehensive after-sales service to ensure customers receive timely technical support and solutions during use.