The pneumatic Y-type three-way ball valve is designed for seamless fluid control in industrial systems, providing automated operation and efficient fluid guidance while reducing resistance. Made from robust forged steel, the valve ensures long-term durability and stable performance under harsh conditions. The T-shaped design flexibly manages fluid paths, making it ideal for systems requiring precise flow distribution or redirection. Pneumatic operation not only enhances system automation and reduces the need for manual control but also significantly boosts overall efficiency.

● Y-Shaped Design: This design can achieve efficient fluid diversion and distribution between a single inlet and two outlets.

● Multiple Sealing Options: The valve offers a variety of sealing options, including soft seals, hard seals, and fireproof seats, ensuring that specific requirements are met under different working conditions. Valves with diameters less than DN150 use a floating ball design, while those with diameters greater than DN150 use a fixed ball design.

● Emergency Sealing Structure: Auxiliary sealing structure is installed on the valve seat, oil injection valve can be added to provide temporary sealing in emergency, and the valve stem can be extended to meet the requirements of underground installation.

| DN | KV | ACTUATOR MODEL | ACTION TIME | |

| FULLY OPEN | FULLY CLOSED | |||

| 15 | 20 | GTX63 | 0.5 | 0.5 |

| 20 | 38 | GTX63 | 0.5 | 0.5 |

| 25 | 72 | GTX63 | 0.5 | 0.5 |

| 32 | 110 | GTX75 | 0.5/0.6 | 0.6/0.8 |

| 40 | 170 | GTX75 | 0.5/0.6 | 0.6/1.0 |

| 50 | 270 | GTX83 | 0.5/0.6 | 0.8/1.2 |

| 65 | 380 | GTX110 | 0.7/1.0 | 0.8/1.2 |

| DN | KV | ACTUATOR MODEL | ACTION TIME | |

| FULLY OPEN | FULLY CLOSED | |||

| 80 | 510 | GTX118 | 0.8/1.0 | 1.0/1.5 |

| 100 | 940 | GTX160 | 1.0/1.2 | 1.0/2.0 |

| 125 | 1400 | GTX210 | 1.1/1.6 | 1.3/2.3 |

| 150 | 2200 | GTX210 | 1.2/2.0 | 1.5/2.5 |

| 200 | 3500 | GTX254 | 3.5/4.5 | 4.5/6.0 |

| 250 | 5200 | GTX254 | 4.0/5.0 | 5.0/6.0 |

| 300 | 8500 | GTX255 | 5.0/6.0 | 5.5/7.0 |

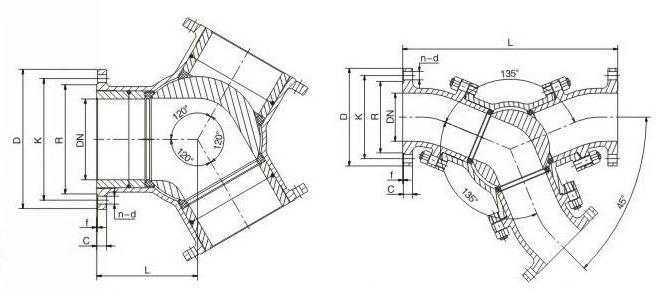

External Dimension and Weight:

| DN | L0 | L | H1 | H2 | H3 | Weight(kg) | ||

| PN16/40 | PN63 | PN16/40 | PN63 | |||||

| 15 | 133 | 130 | 165 | 54 | 177 | 47 | 6.5 | 7.5 |

| 20 | 133 | 130 | 190 | 54 | 177 | 47 | 7 | 8.5 |

| 25 | 133 | 140 | 216 | 60 | 177 | 52 | 9 | 11 |

| 32 | 182 | 165 | 229 | 67 | 198 | 59 | 13.5 | 16 |

| 40 | 182 | 165 | 241 | 78 | 198 | 66 | 18 | 21.5 |

| 50 | 182 | 203 | 292 | 88 | 223 | 78 | 26 | 32 |

| 65 | 222 | 222 | 330 | 98 | 275 | 91 | 33 | 41 |

| 80 | 294 | 241 | 356 | 121 | 275 | 106 | 48 | 58 |

| 100 | 380 | 305 | 406 | 144 | 353 | 130 | 88 | 106 |

| 125 | 450 | 356 | 455 | 148 | 420 | 150 | 115 | 138 |

| 150 | 450 | 394 | 495 | 176 | 420 | 172 | 200 | 240 |

| 200 | 603 | 457 | 597 | 226 | 504 | 215 | 245 | 294 |

| 250 | 603 | 533 | 673 | 281 | 504 | 270 | 340 | 408 |

| 300 | 603 | 610 | 762 | 320 | 515 | 330 | 456 | 548 |

| Form | Type T,L three way ball valve |

| Inside nominal diameter DN(mm) | DN15-DN300 |

| Nominal pressure | 1.6 2.5 4.0 6.4Mpa |

| Liquid range | Air ,water, gas ,oil and petrochemical products corrosive medium |

| Working temperature | Hard seal:-40 --300 Soft seal:-40 --180 |

| Spillage | 0 conform to ANSIB16.104standard |

| Main material | Valve body : WCB 304 316 316L Spool: 304 316 316L |

| Seat form | Stainless steel movable hard seal, PTFE soft seal |

| Surface preparation | Polishing |

| Port Size | 2"--12" |

| Pressure | 150LB--1500LB |

| Temperature of Media | High Temperature |

| Media | gas oil and water ect |

| Drive means | Manual , pneumatic , electric |

| Type of connection | Flange , thread , butt welded |

| Material | SS, CS |

| Packaging & Delivery | Plywood case or buyer request |

Q1:Can this valve be used for both diversion and merging of fluids?

Yes, the Y-shaped design allows the valve to efficiently divert fluid from one inlet to two outlets or merge two fluid flows into a single outlet, making it versatile for various fluid control needs.

Q2:How does the Y-shaped design improve fluid control?

The Y-shaped design allows for seamless diversion and distribution of fluid, ensuring smooth flow and reducing pressure drop, which is ideal for applications requiring flexible flow direction.

Q3:What are the benefits of using this valve in medium mixing or shunting applications?

This valve provides excellent control over fluid flow, allowing for precise mixing or redirection of fluid between multiple paths, enhancing the efficiency of medium mixing or shunting processes in complex systems.

The pneumatic forging Y-type three-way ball valve produced by our company has excellent flow control performance, and can reduce the turbulence of fluid to a minimum, ensuring smooth operation. The valve is made of high strength forged steel, with excellent robustness and durability, is an ideal choice for all kinds of industrial pipeline applications.