The QJ41M integrated high-temperature ball valve is a ball valve designed specifically for high-temperature environments, with characteristics such as high temperature resistance, wear resistance, and corrosion resistance. It is suitable for media such as water vapor, oil, thermal oil, and acid.

● Easy Operation: Simply rotate the sphere to complete the switch action, without the need for additional tools or complex operations, thus significantly improving work efficiency.

● High Temperature Resistance: The valve body is usually made of high-quality cast steel, which can operate continuously and stably in high temperature, high pressure, and corrosive media, thereby extending the service life of the equipment.

● Convenience: Compact structure, small installation space requirement, and simple installation process. At the same time, the maintenance cost is low, and only regular inspection and replacement of seals and other vulnerable parts can keep it in good operating condition.

| No. | Parts Name | Material |

| 1 | Body | A105+ENP, A182 F6, F304, F304L, F316, F316L, F51 |

| 2 | Seat | PTFE, R-PTFE, PEEK, PPL |

| 3 | Anti-static Spring | Stainless Steel |

| 4 | Stem | A105+ENP, A182 F6, F304, F304L, F316, F316L, F51 |

| 5 | O-ring | NBR, PTFE |

| 6 | Limited Plate | 1015+Cr, Carbon Steel+Cr |

| 7 | Lever | A216 WCB, 1025+Cr |

| 8 | Fix Nut | Stainless Steel |

| 9 | Backup Ring | A182 F304, F316 |

| 10 | Packing | PTFE, Graphite |

| 11 | Positioning Pin | Stainless Steel |

| 12 | Thrust Washer | PTFE |

| 13 | Gasket | PTFE, Graphite |

| 14 | Ball | A105+ENP, A182 F6, F304, F304L, F316, F316L, F51 |

| 15 | Bonnet | A105+ENP, A182 F6, F304, F304L, F316, F316L, F51 |

| 16 | O-ring | NBR, PTFE |

| 17 | Stud | A193 B7, B7M, B8, B8M |

| 18 | Nut | A194 2H, 2HM, 8, 8M |

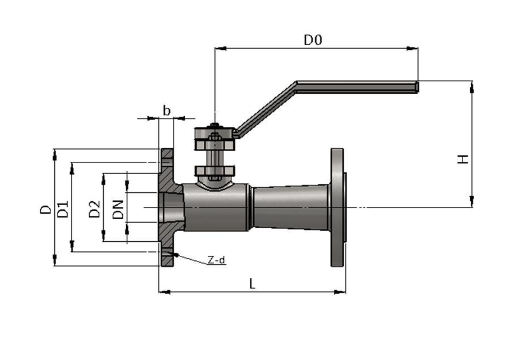

Main Dimensions

| Model | Size(mm) | Dimensions(mm) | ||||||||

| QJ41M | inch | DN | L | D | D1 | D2 | b | Z-Φd | H | W |

| 3/4″ | 20 | 117 | 98 | 70 | 43 | 12 | 4-Φ15 | 75 | 130 | |

| 1″ | 25 | 127 | 108 | 79.5 | 51 | 12 | 4-Φ15 | 85 | 150 | |

| 11/4″ | 32 | 140 | 117 | 89 | 64 | 13 | 4-Φ15 | 96 | 190 | |

| 11/2″ | 40 | 165 | 127 | 98.5 | 73.2 | 15 | 4-Φ15 | 107 | 230 | |

| 2″ | 50 | 178 | 152 | 120.7 | 92 | 16 | 4-Φ19 | 118 | 240 | |

| 21/2″ | 65 | 190 | 177.8 | 139.7 | 104.7 | 18 | 4-Φ19 | 145 | 280 | |

| 3″ | 80 | 203 | 190.5 | 152.4 | 127 | 19 | 4-Φ19 | 160 | 310 | |

| 4″ | 100 | 229 | 229 | 190.5 | 157 | 24 | 8-Φ19 | 185 | 330 | |

| 5″ | 125 | 356 | 254 | 216 | 185.7 | 26 | 8-Φ22 | 230 | 600 | |

| 6″ | 150 | 394 | 279 | 241.3 | 216 | 26 | 8-Φ22 | 260 | 800 | |

| 8″ | 200 | 457 | 343 | 298.5 | 270 | 29 | 8-Φ22 | 310 | 1000 | |

| 10″ | 250 | 533 | 406 | 362 | 324 | 31 | 12-Φ25 | 350 | 1200 | |

| Test Item | Shell Test | Sealing Test | Back Seal Test | Air Test | |||||

| Medium | Water | Air | |||||||

| Unit | MPa | Lbf/in2 | MPa | Lbf/in2 | MPa | Lbf/in2 | MPa | Lbf/in2 | |

| Test Pressure | 150 | 3.1 | 450 | 2.2 | 315 | 2.2 | 315 | 0.5-0.7 | 60-100 |

| 300 | 7.8 | 1125 | 5.6 | 815 | 5.6 | 815 | |||

| 400 | 10.3 | 1500 | 7.6 | 1100 | 7.6 | 1100 | |||

| 600 | 15.3 | 2225 | 11.2 | 1630 | 11.2 | 1630 | |||

| 900 | 23.1 | 3350 | 16.8 | 2440 | 16.8 | 2440 | |||

Product Display

Q1:What is the benefit of the floating ball design?

The floating ball design allows for smooth, efficient flow control as the ball moves with the flow of the fluid, ensuring minimal resistance and optimal performance.

Q2:What is the valve's temperature and pressure range?

The valve can handle temperatures from -40ºC to 300ºC (hard seal) or -40ºC to 180ºC (soft seal) and is rated for nominal pressures from PN1.6 to 6.4 MPa.

Our integral high-temperature ball valve is made of advanced materials and exquisite craftsmanship, ensuring its excellent heat resistance and long service life. The valve is designed to be compact and easy to install, greatly saving space and time costs. Our products undergo rigorous quality testing to ensure that every detail meets industry standards, providing you with a worry free user experience. We provide comprehensive after-sales service, whether it's technical consultation or repair support, we can respond quickly to meet your needs.