Views: 198 Author: Site Editor Publish Time: 2025-06-25 Origin: Site

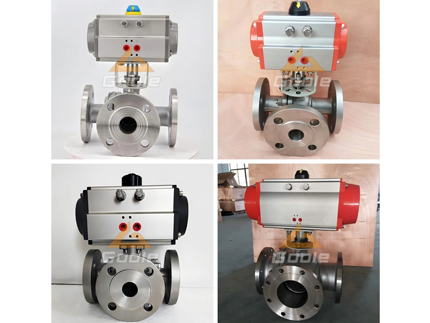

A three way ball valve is a highly versatile device used in various industrial systems for mixing, diverting, and distributing flow. Whether in chemical processing, food and beverage pipelines, or HVAC systems, these valves help manage complex flow operations with precision and efficiency. However, achieving their full potential depends largely on proper installation. Incorrect setup can lead to serious problems like leaks, misrouting of flow, premature wear, or even complete valve failure.

This blog outlines all the essential installation do’s and don’ts for three way ball valves—whether you're using L-port or T-port types, and whether the actuator is manual, pneumatic, or electric.

One of the biggest sources of error during installation is misunderstanding the valve’s internal design. Three way ball valves mainly come in two port configurations:

L-Port Valve: Designed to allow flow between two ports at a time, typically used to divert flow from a common inlet to one of two outlets or vice versa.

T-Port Valve: Allows flow to connect any two or all three ports simultaneously, suitable for mixing or blending fluids or for more complex routing.

Installing an L-port valve where a T-port valve is required (or vice versa) can cause blocked flow, incomplete mixing, or dangerous pressure buildups. Before installation, always:

Check the manufacturer’s markings or technical datasheets indicating the port type.

Verify flow direction arrows on the valve body.

Match the valve configuration with your system’s process flow diagrams.

In some cases, valves are also labeled with flow schematics directly on the valve handle or body for quick reference.

Piping systems often contain debris such as weld slag, rust, dust, or metal shavings from fabrication. If not cleaned before valve installation, these particles can:

Damage the ball and seat sealing surfaces

Cause premature seat wear and leaks

Lead to valve handle sticking or actuator jamming

To avoid these issues:

Flush pipelines with clean water, compressed air, or compatible solvents.

Inspect pipe ends and valve ports visually and with cleaning brushes if necessary.

For sensitive systems, use filtration or strainers upstream of the valve to prevent debris ingress during operation.

Taking these steps preserves the valve's internal integrity and ensures smooth operation.

Use high-quality PTFE tape or pipe thread sealant compounds on male threads.

Apply sealant only to the threads—avoid excess that could flake into the valve body.

Always wrap PTFE tape in the direction of thread tightening to prevent unraveling.

Install new compatible gaskets rated for your system’s pressure, temperature, and fluid.

Use a torque wrench and tighten flange bolts in a cross/star pattern to evenly compress the gasket and avoid leaks.

Follow manufacturer or engineering specifications for bolt torque values.

Over- or under-tightening can cause damage, leaks, or misalignment, so precision here is critical.

Improper alignment can severely impact valve and actuator performance by:

Causing side loading on the valve stem, increasing wear.

Introducing strain on the valve body and piping, leading to cracks or leaks.

Resulting in actuator failure if the stem or shaft binding occurs.

Use spirit levels, laser alignment tools, or alignment jigs to ensure that:

The valve is centered and parallel to the pipeline.

Actuators and manual handles have a clear, unobstructed rotation path.

Pipes and valve flanges are fully supported to prevent stress transmission to the valve.

Proper alignment minimizes wear and facilitates easy operation.

A well-designed piping layout considers future maintenance needs. Without sufficient clearance:

Valve handles may not fully rotate.

Pneumatic or electric actuators may be inaccessible for wiring or air tubing.

Removal and replacement of the valve become difficult and time-consuming.

Ideally, leave at least 12–18 inches of clearance around the valve for tool access and handle movement. For automated valves, check actuator dimensions and wiring needs.

Many three way ball valves depend on gravity for seal seating, drainage, or lubrication. Installing valves upside down or against recommended orientation can:

Cause improper sealing and internal leakage.

Allow debris to accumulate, jamming the valve.

Confuse process logic or flow control functions.

Always consult the valve’s installation manual and respect flow direction arrows.

Applying too much torque can:

Crack valve bodies (especially PVC, CPVC, or brass).

Damage internal seals or ball seats.

Strip pipe or valve threads.

Use a torque wrench and adhere to manufacturer specifications to avoid damage. If in doubt, consult with the valve supplier.

Material incompatibility causes premature failure:

Using brass valves on stainless steel pipes can cause galvanic corrosion.

EPDM or other elastomer seals may degrade in the presence of certain chemicals or high temperatures.

Plastic valves are often incompatible with some solvents or oils.

Always verify the chemical compatibility of valve body, seats, seals, and piping materials with your fluid.

Skipping operational testing risks undiscovered issues:

The valve may not fully open or close.

Leaks can go unnoticed until system pressurization.

Actuators may fail to respond or have incorrect stroke limits.

After installation:

Manually or automatically cycle the valve through all ports.

Pressure test the system to check for leaks.

Verify actuator calibration and limits.

Early detection prevents costly downtime later.

Tight layouts or improper pipe support can:

Restrict valve handle rotation.

Stress valve bodies with pipe weight.

Make actuator wiring or air lines inaccessible.

Maintain easy access for operation, adjustments, and servicing.

Once the valve is installed:

✅ Pressurize the system slowly and inspect for visible leaks

✅ Cycle the valve through all possible flow configurations

✅ Verify actual flow direction matches design logic

✅ Check actuator limits and calibration if electric or pneumatic

✅ Log the installation date and valve type for maintenance history

Routine inspections should be scheduled, particularly in high-cycle or high-pressure applications.

Even with a flawless installation, three way ball valves require routine maintenance:

Quarterly inspections in harsh environments (chemicals, acids, high temperatures)

Lubrication of seals and stem if recommended

Valve cycling in unused configurations to prevent clogging

Replacement of worn seats, seals, or stems as needed

Neglecting maintenance can lead to flow restriction, handle stiffness, and leakage over time.

Mistake | Consequence | Fix |

Installed wrong valve (L vs T port) | Incorrect flow pattern | Replace with correct configuration |

Valve handle stuck | Debris or actuator misalignment | Clean internals, check actuator |

Leakage at threads | Over-torquing or poor sealing | Reinstall with proper torque and sealant |

Flow doesn't match design | Misaligned valve | Check port alignment, inspect internals |

Yes, but it depends on the flow direction and actuator. Always check with the manufacturer’s recommendations, as some valves may not perform well when installed in non-horizontal orientations.

Basic tools like a pipe wrench, torque wrench, thread sealant, and level are usually sufficient. For actuated valves, electrical or pneumatic tools may be required for setup.

Manufacturers usually mark this on the valve body. Alternatively, you can refer to the flow diagram on the nameplate or technical datasheet.

For most threaded valves, yes. However, in high-pressure or aggressive fluid systems, you may want to use liquid thread sealant or gaskets for extra protection.

Installing a three way ball valve is more than just tightening a few fittings—it’s a strategic task that affects the performance and reliability of your entire fluid system. By following the installation best practices and avoiding the common pitfalls listed above, you can enjoy long-term, leak-free operation.

Whether you're managing a complex chemical mixing system, a diverting network in HVAC, or an automated process line, choosing the right valve and installing it properly ensures optimal results.

Ready to find the right three way ball valve for your application? Contact Valve Technology Co., Ltd. for professional support and reliable valve solutions.