| Availability: | |

|---|---|

| Quantity: | |

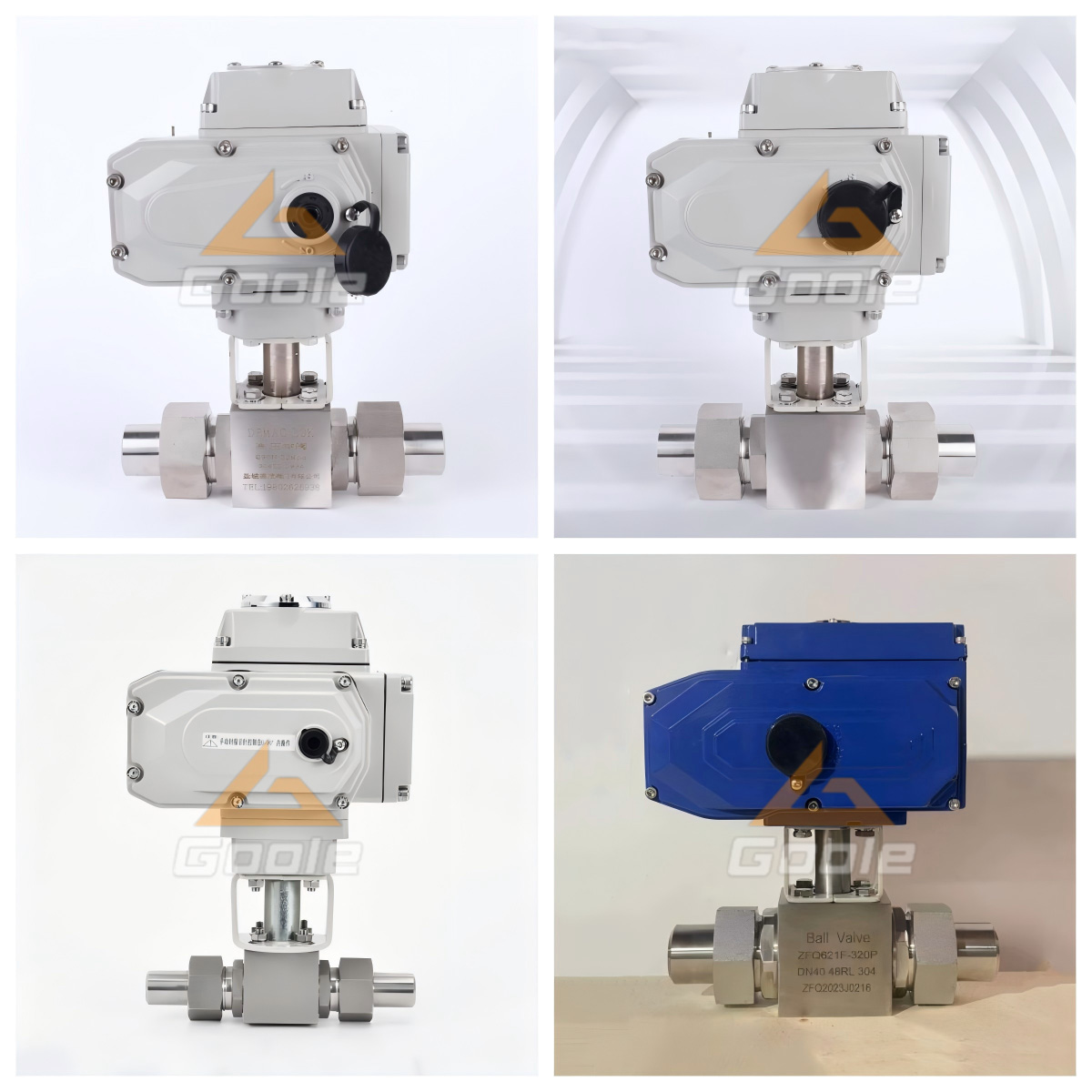

The vertical cross-section of the electric high-pressure ball valve is divided into three parts along the valve body channel, located at two positions on the valve seat. The entire valve is designed symmetrically around the central axis of the valve stem. It is mainly used in pipeline systems to cut off, distribute, and change the direction of fluid flow. Its rotating mechanism can accurately position the center of the ball in high-pressure environments, ensuring excellent operational performance. The electric actuator adopts an integrated design, and only requires a 220V power supply to directly adjust the switch state. In addition, it can also be equipped with a built-in servo module that operates through control signals (4-20mA or 1-5VDC) and single-phase power supply.

● Special Design: The valve is symmetrically designed along the central axis of the valve stem, mainly used for cutting, distributing, and changing the direction of the medium in the pipeline.

● Good Operational Performance: Thanks to its large rotating shaft structure, the ball can maintain precise center position even in high-pressure environments, ensuring smooth operation of the valve.

● Spring Structure: The standard valve seat adopts a spring structure, which pushes the valve seat close to the sphere, thereby ensuring the bi-directional sealing performance of the inlet and outlet.

● Preventing Leakage: The built-in exhaust valve can discharge the gas inside the valve body to the outside, and the explosion-proof protection structure effectively avoids the risk of leakage.

DN | Pipe Thread | size(mm) | Pipe Thread | size(mm) | |||||||

d | L | H | W | E | H | W | SW | L | |||

6 | 1/4 | 11 | 70 | 43 | 108 | 42.5 | - | - | - | - | 70 |

10 | 3/8 | 11 | 70 | 43 | 108 | 42.5 | - | - | - | - | - |

15 | 1/2 | 11 | 85 | 43 | 108 | 42.5 | 1/2 | 68 | 130 | 41 | 85 |

20 | 3/4 | 14 | 95 | 45.5 | 146 | 47.5 | 3/4 | 77 | 180 | 46 | 95 |

25 | 1 | 21 | 105 | 59.5 | 146 | 52.5 | 1 | 82 | 180 | 55 | 105 |

32 | 1 1 /4 | 25 | 120 | 64.5 | 146 | 60 | 1 1 /4 | 115 | 300 | 70 | 120 |

40 | 1 1 /2 | 32 | 130 | 76 | 254 | 65 | 1 1 /2 | 120 | 300 | 80 | 130 |

50 | 2 | 38 | 150 | 81 | 254 | 75 | 2 | 130 | 300 | 100 | 150 |

| Nominal pressure | PN1.6~6.4MPa |

| Nominal diameter | 20~400mm |

| Appliable Temperature | Hard Seal:-40~300ºC Soft Seal: -40~180ºC |

| Applicable medium | Water,gas,oil quality and so on |

| Driving Means | Manual ,Electric, Worm wheels, Pneumatic |

| Body materials | WCB, CF8, CF8M, CF3M |

| Stem | 2Cr13, 304, 316 |

| Rotary angle | 90° |

| Valve Seat | PTFE, 0Crl, 7Ni4Cu4Nb |

| Core Material | CF8, CF8M, CF3M |

Q1:What is the main suitable of this valve?

This product is especially suitable for steel, aluminum, fiber, small solid particles, pulp, coal ash, petroleum gas and other media.

Q2:What mechanical principle is used?

The key component of the valve is a sphere with a central hole. By precisely rotating the sphere, it can align or misalign the channels with the inlet and outlet channels of the valve, thereby controlling the fluid state to achieve opening or closing effects. This component is controlled by a pneumatic actuator, which rotates the sphere to perform functions such as opening, closing, and regulating fluid flow. In addition, the internal threaded connection significantly enhances the sealing performance of the system.

The electric high-pressure welded ball valve is made of high-quality materials to ensure its durability and stability. Its unique design endows the ball valve with excellent sealing performance, effectively preventing leakage problems and improving system safety. The ball valve is easy to operate; Its pneumatic drive allows for quick opening and closing, significantly improving work efficiency. We also offer various sizes and types to meet the specific needs of different customers. Choosing our electric high-pressure welded ball valve is undoubtedly a wise decision.