| Availability: | |

|---|---|

| Quantity: | |

The fiberglass ball valve is crafted from specialized fiberglass materials and offers several advantages, including corrosion resistance, a lightweight structure, high strength, and anti-aging properties. The valve's design is unique, featuring a ball that is cast using precision casting technology to ensure superior sealing performance. This enables the valve to operate reliably over extended periods, even under harsh conditions. These valves not only demonstrate exceptional corrosion resistance, capable of enduring the erosion from various chemical media, thereby extending their service life, but also exhibit high-strength characteristics, are lightweight, and are easy to install and maintain. Furthermore, they can endure mechanical impacts and pressure variations, which further enhances the stability and durability of the valve.

● Excellent Corrosion Resistance: The valve is capable of withstanding erosion from various chemical media, making it suitable for a range of harsh working environments and significantly extending its service life.

● High Strength Properties: The ball valve is lightweight, easy to install, and maintain.

● Strong Impact Resistance: The valve can endure certain mechanical impacts and pressure fluctuations, enhancing its stability and durability.

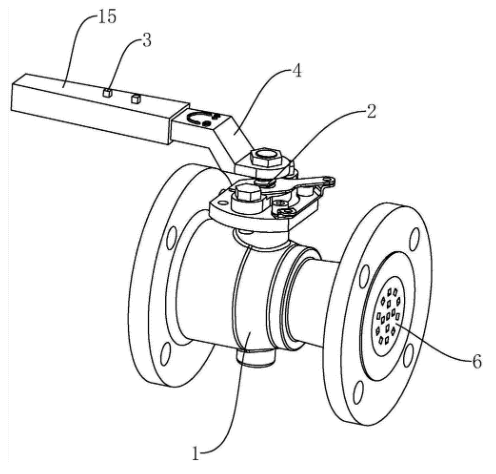

| No | Part Name | ASTM Material | ||

| Carbon steel | 18Cr-9Ni-2Mo | Carbon steel | ||

| 1 | Body | A216-WCB | A351-CF8M | A352-LCB |

| 2 | Bonnet | A216-WCB | A351-CF8M | A352-LCB |

| 3 | Ball | A182-F304 | A182-F316 | A182-F304 |

| 4 | Stem | A276-304 | A276-316 | A276-304 |

| 5 | Seat ring | R.PTFE | ||

| 6 | Gasket | Graphite+304 | PTFE | Graphite+304 |

| 7 | Stud | A193-B7 | A193-B8 | A320-L7 |

| 8 | Nut | A194-2H | A194-8 | A194-4 |

| 9 | Packing | PTFE | ||

| 10 | Gland flange | A216-WCB | A351-CF8M | A352-LCB |

| 11 | Gland bolt | A193-B7 | A193-B8 | A193-B7 |

| 12 | Stop plate | Carbon steel | Carbon steel+Zn | Carbon steel |

| 13 | Handle | Carbon steel | ||

Main Dimensions.

150LB

| Size | in | 1/2 | 3/4 | 1 | 1 1/2 | 2 | 2 1/2 | 3 | 4 | 6 | 8 | 10 | 12 |

| mm | 15 | 20 | 25 | 40 | 50 | 65 | 80 | 100 | 150 | 200 | 250 | 300 | |

| L(RF) | in | 4.25 | 4.62 | 5.00 | 6.50 | 7.00 | 7.50 | 8.00 | 9.00 | 15.50 | 18.00 | 21.00 | / |

| mm | 108 | 117 | 127 | 165 | 178 | 190 | 203 | 229 | 394 | 457 | 533 | / | |

| L1(BW) | in | 5.50 | 6.00 | 6.50 | 7.50 | 8.50 | 9.50 | 11.12 | 12.00 | 18.00 | 20.50 | 22.00 | / |

| mm | 140 | 152 | 165 | 190 | 216 | 241 | 283 | 305 | 457 | 521 | 559 | / | |

| H | in | 2.12 | 2.12 | 2.75 | 3.50 | 4.12 | 6.12 | 7.25 | 8.00 | 10.00 | 11.00 | 13.50 | / |

| mm | 55 | 55 | 70 | 90 | 105 | 155 | 185 | 205 | 255 | 280 | 345 | / | |

| W | in | 5 | 5 | 6 | 8 | 14 | 16 | 20 | 20 | 24 | 32 | 32 | / |

| mm | 130 | 130 | 160 | 200 | 350 | 400 | 500 | 500 | 600 | 800 | 800 | / | |

| WT(Kg) | RF | 2.3 | 3 | 4.5 | 7 | 9.5 | 15 | 19 | 33 | 93 | 160 | 200 | / |

| BW | 1.8 | 2.8 | 3.7 | 6.2 | 8.5 | 14 | 21 | 35 | 98 | 170 | 225 | / |

300LB

| Size | in | 1/2 | 3/4 | 1 | 1 1/2 | 2 | 2 1/2 | 3 | 4 | 6 | 8 | 10 | 12 |

| mm | 15 | 20 | 25 | 40 | 50 | 65 | 80 | 100 | 150 | 200 | 250 | 300 | |

| L(RF) | in | 5.50 | 6.00 | 6.50 | 7.50 | 8.50 | 9.50 | 11.12 | 12.00 | 15.88 | 19.75 | / | / |

| mm | 140 | 152 | 165 | 190 | 216 | 241 | 283 | 305 | 403 | 502 | / | / | |

| L1(BW) | in | 5.50 | 6.00 | 6.50 | 7.50 | 8.50 | 9.50 | 11.12 | 12.00 | 18.00 | 20.50 | / | / |

| mm | 140 | 152 | 165 | 190 | 216 | 241 | 283 | 305 | 457 | 521 | / | / | |

| H | in | 2.12 | 2.12 | 2.75 | 3.50 | 4.12 | 6.12 | 7.25 | 8.00 | 10.00 | 11.00 | / | / |

| mm | 55 | 55 | 70 | 90 | 105 | 153 | 187 | 206 | 255 | 280 | / | / | |

| W | in | 5 | 5 | 6 | 8 | 14 | 16 | 20 | 20 | 24 | 32 | / | / |

| mm | 130 | 130 | 160 | 200 | 350 | 400 | 500 | 500 | 600 | 800 | / | / | |

| WT(Kg) | RF | 2.5 | 3.5 | 5.5 | 10.5 | 14.5 | 23.5 | 30 | 55 | 118 | 200 | / | / |

| BW | 1.8 | 2 | 3.2 | 5.5 | 8.7 | 15 | 18 | 36 | 85 | 152 | / | / |

600LB

| Size | in | 1/2 | 3/4 | 1 | 1 1/2 | 2 | 2 1/2 | 3 | 4 | 6 | 8 | 10 | 12 |

| mm | 15 | 20 | 25 | 40 | 50 | 65 | 80 | 100 | 150 | 200 | 250 | 300 | |

| L/L1(RF/BW) | in | 6.50 | 7.50 | 8.50 | 9.50 | 11.50 | 13.00 | 14.00 | 17.00 | / | / | / | / |

| mm | 165 | 190 | 216 | 241 | 292 | 330 | 356 | 432 | / | / | / | / | |

| L2(RTJ) | in | / | / | / | / | 11.62 | 13.12 | 14.12 | 17.12 | / | / | / | / |

| mm | / | / | / | / | 295 | 333 | 359 | 435 | / | / | / | / | |

| H | in | 2.38 | 2.38 | 3.00 | 4.00 | 4.75 | 6.88 | 8.38 | 9.25 | / | / | / | / |

| mm | 61.5 | 61.5 | 78 | 101 | 120 | 174 | 212 | 234 | / | / | / | / | |

| W | in | 5 | 6 | 8 | 14 | 16 | 20 | 24 | 24 | / | / | / | / |

| mm | 130 | 160 | 200 | 350 | 400 | 500 | 600 | 600 | / | / | / | / | |

| WT(Kg) | RF/RTJ | 3.3 | 4.5 | 7.2 | 13.5 | 19 | 31 | 39 | 71 | / | / | / | / |

| BW | 2.6 | 3.1 | 4.8 | 8 | 13 | 22 | 27 | 53 | / | / | / | / |

| Size | 1/2"~12" |

| Pressure rating | 150LB/300LB/600LB |

| Body material | Carbon steel,stainless steel or other material |

| Trim material | CS+ENP,13Cr,F304,F316,INCONEL,MONEL,DUPLEX.,etc |

| Driving modes | Lever,Gear,Pneumatic,Electric |

Q1:What is the benefit of the floating ball design?

The floating ball design allows for smooth, efficient flow control as the ball moves with the flow of the fluid, ensuring minimal resistance and optimal performance.

Q2:What is the valve's temperature and pressure range?

The valve can handle temperatures from -40ºC to 300ºC (hard seal) or -40ºC to 180ºC (soft seal) and is rated for nominal pressures from PN1.6 to 6.4 MPa.

Glass fiber materials exhibit excellent corrosion resistance, capable of withstanding erosion caused by various chemical media. This ensures the stable operation of valves under harsh working conditions and significantly extends their service life. Our ball valves are lightweight, easy to install and maintain, reducing challenges in transportation and operation. Furthermore, glass fiber ball valves have strong impact resistance, capable of withstanding mechanical impacts and pressure fluctuations, thereby enhancing the stability and durability of the valve. Choosing our glass fiber ball valves will provide your engineering projects with an efficient, reliable, and cost-effective solution.