Forged steel ball valves are used in the petroleum industry to cut or connect pipeline media between nominal pressures of 150 to 1500 and working temperatures of 600 ℃. Chemical industry, fossil fuel power plants. The sealing ring material for forged ball valves can be PTFE, RTFE, nylon PEEK、DEVLON、 Carbon steel+filled with PTFE, etc.

● Floating Ball Design: By allowing the ball to move with the flow of the medium, it ensures smooth operation and efficient fluid control.

● Threaded Connections: Easy to install and maintain, providing safe and leak proof connections in piping systems.

● Quick Operation: The valve only needs to be rotated 90 degrees to open or close, providing fast and simple flow control.

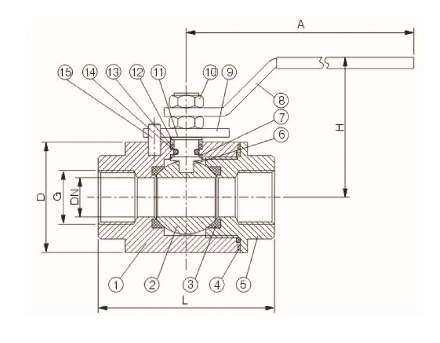

| 1 | CAP | SS304/SS316/A105 | 9 | THRUST WASHER | PTFE |

| 2 | BOLT WASHER | SS304/SS | 10 | PACKING | PTFE |

| 3 | HEX NUT | SS304/SS | 11 | GLAND | SS304/SS |

| 4 | BOLT | SS304/SS | 12 | LOCATING PIECE | SS304/SS |

| 5 | BODY | SS304/SS316/A105 | 13 | HANDLE | SS304/SS |

| 6 | SEAT | PTFE | 14 | STEM NUT | SS304/SS |

| 7 | BALL | SS316/SS304/SS | 15 | PLASTIC COVER | PLASTIC |

| 8 | STEM | SS316/SS304/SS | 16 | DOWEL | SS304/SS |

Main Dimensions

| Size | in | 1/2 | 3/4 | 1 | 1 1/2 | 2 | 2 1/2 | 3 | 4 | 6 | 8 | 10 | 12 |

| mm | 15 | 20 | 25 | 40 | 50 | 65 | 80 | 100 | 150 | 200 | 250 | 300 | |

| L(RF) | in | 4.25 | 4.62 | 5.00 | 6.50 | 7.00 | 7.50 | 8.00 | 9.00 | 15.50 | 18.00 | 21.00 | / |

| mm | 108 | 117 | 127 | 165 | 178 | 190 | 203 | 229 | 394 | 457 | 533 | / | |

| L1(BW) | in | 5.50 | 6.00 | 6.50 | 7.50 | 8.50 | 9.50 | 11.12 | 12.00 | 18.00 | 20.50 | 22.00 | / |

| mm | 140 | 152 | 165 | 190 | 216 | 241 | 283 | 305 | 457 | 521 | 559 | / | |

| H | in | 2.12 | 2.12 | 2.50 | 3.38 | 4.00 | 6.00 | 7.00 | 9.25 | 9.88 | 11.00 | 12.62 | / |

| mm | 55 | 55 | 65 | 85 | 100 | 150 | 180 | 235 | 250 | 280 | 320 | / | |

| W | in | 8 | 8 | 12 | 12 | 16 | 16 | 24 | 24 | 24 | 24 | 32 | / |

| mm | 200 | 200 | 300 | 300 | 400 | 400 | 600 | 600 | 600 | 600 | 800 | / | |

| WT(Kg) | RF | 3.1 | 4.1 | 6 | 9.5 | 12.8 | 20 | 26 | 45 | 126 | 216 | 270 | / |

| BW | 2.6 | 3.9 | 5.2 | 8.7 | 11.8 | 19 | 28 | 47 | 131 | 226 | 295 | / |

| End Connection | threaded (THD) / butt welded (BW) / socket welded (SW) |

| Pressure Rating | 150lb- 1500lb |

| Specification | 3/8"- 2" |

| Material | A105.F304.F304L.F316.F316L.F11.F22.F5.F9 |

| Executive Standard | API602 |

Note: The dimension of the connecting end can be designed according to customers' special requirements.

Q1:What is the benefit of the floating ball design?

The floating ball design allows for smooth, efficient flow control as the ball moves with the flow of the fluid, ensuring minimal resistance and optimal performance.

Q2:What is the valve's temperature and pressure range?

The valve can handle temperatures from -40ºC to 300ºC (hard seal) or -40ºC to 180ºC (soft seal) and is rated for nominal pressures from PN1.6 to 6.4 MPa.

This application is designed for easy installation and long-term performance. This valve is made of corrosion-resistant carbon steel, ensuring reliable operation under harsh conditions. The floating ball design provides smooth and efficient flow control, while the flange connection ensures a secure fit. Whether you need to control water, gas, or oil in industrial pipeline systems, our valves provide a multifunctional and high-performance solution to meet the needs of various applications.